Carbide Motion Machine Control Software

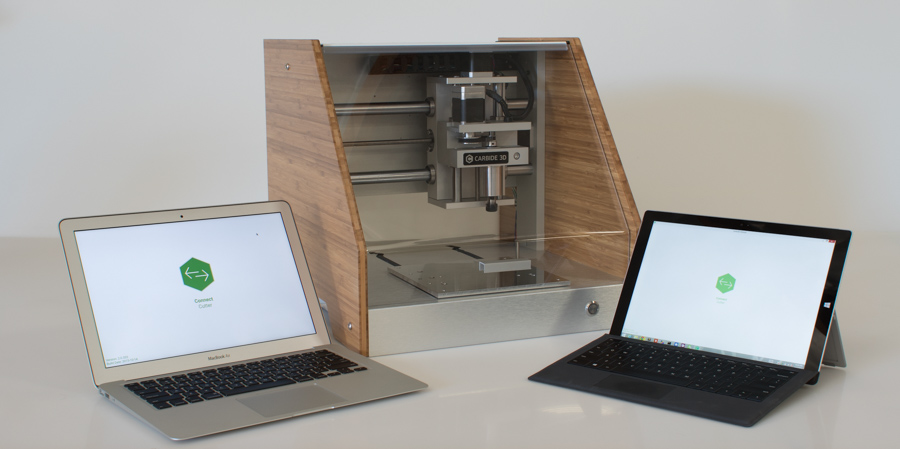

Carbide Motion is the software used to operate your Nomad or Shapeoko CNC machine from Carbide3D.

With Carbide Motion, you'll get up and running quickly, even if you don't know a thing about CNC.

Carbide Motion is the software used to operate your Nomad or Shapeoko CNC machine from Carbide3D.

With Carbide Motion, you'll get up and running quickly, even if you don't know a thing about CNC.

Carbide Motion is a ground-up rethinking of how a machine controller should work. We've focused on just a few things:

BitSetter is a hardware accessory we created to make tool changes easy and reliable so you won't need to fiddle with anything when you need to change tools.

BitSetter is fully integrated into Carbide Motion, and works with Carbide Create and other software to make tool changes a snap.

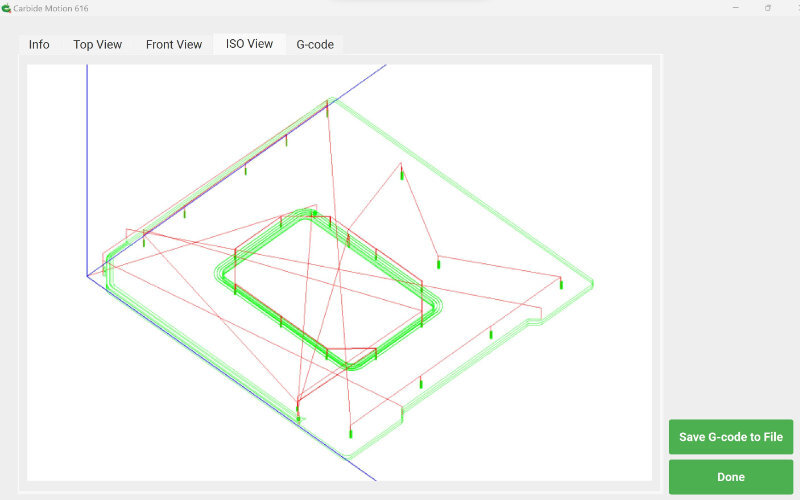

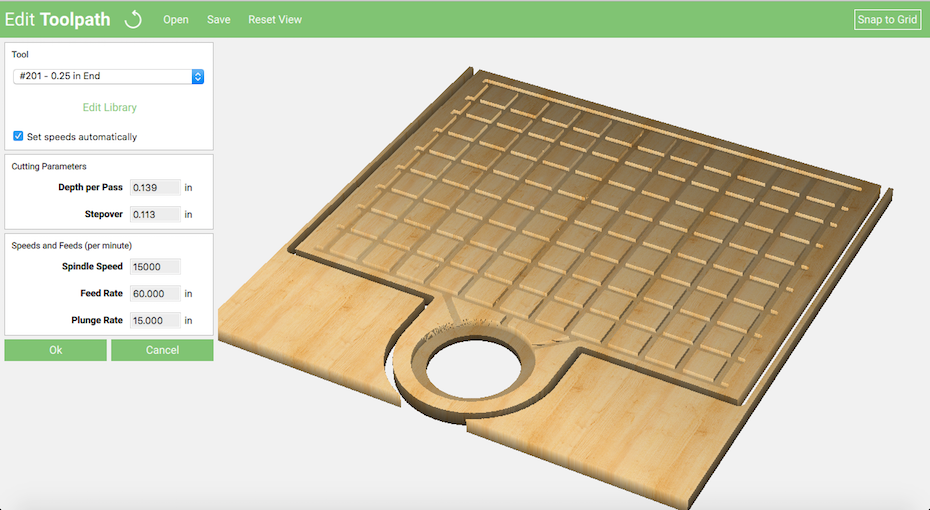

Carbide Motion shows you a 3D view of your toolpaths when loading a project.

This gives you a chance to see if you're loading the correct file, and that you know what to expect before hitting the start button.

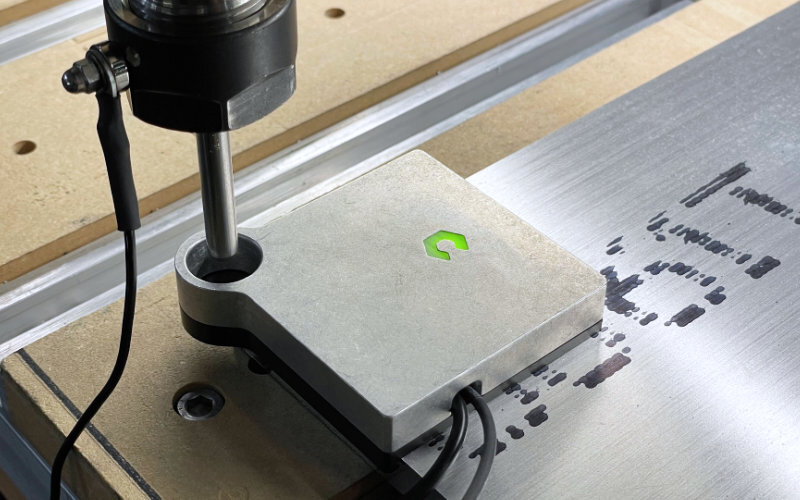

Carbide Motion integrates with BitZero to make zeroing your machine a breeze.

Setting the zero for a project can be confusing for new users, and Carbide Motion with BitZero makes it easy.

Carbide Motion can run full 3D toolpaths on your Shapeoko or Nomad.

Whether you're just cutting a simple 2D shape, or cutting a complicated 3D relief, Carbide Motion has you covered.

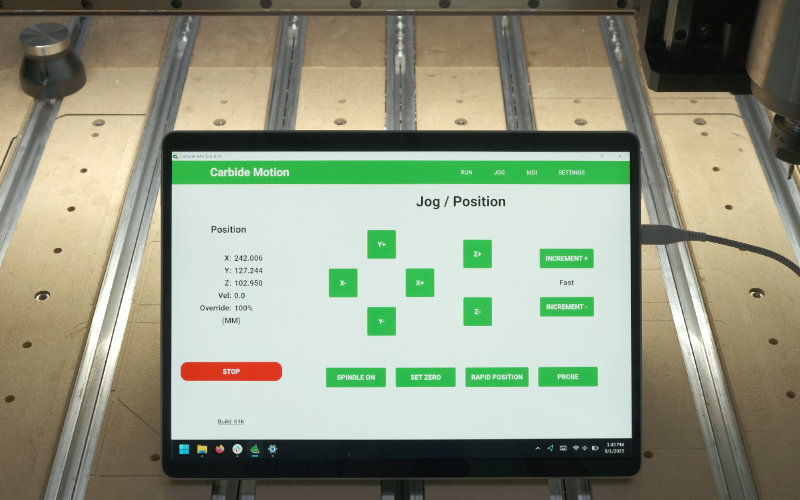

The jog feature found in Carbide Motion allows you to manually move your machine around. From the jog menu you can move to your job zero, and prepare your machine to run a job.

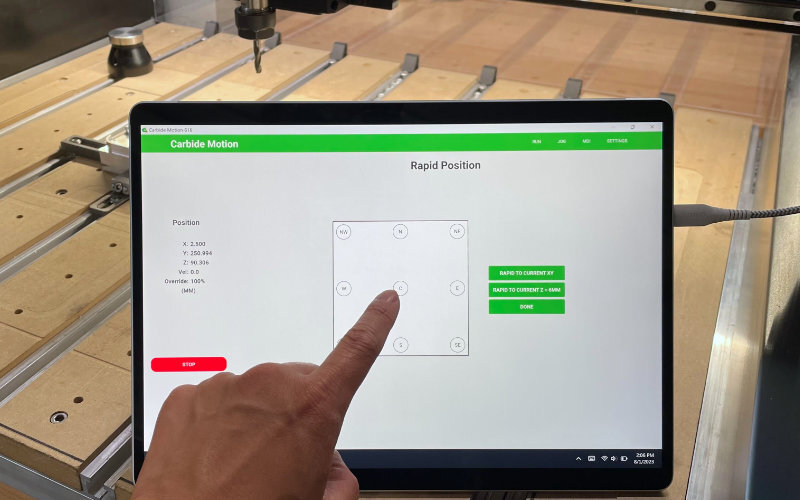

Even on our big industrial machines, jogging can be tedious. To avoid that on Carbide 3D machines, we create the Rapid Positioning feature.

You can quickly move the machine to one of the corners, or the center of the machine with a single click.

We support both Windows and Mac for all of our software.

Carbide Create is the 2.5D CAD/CAM program from Carbide3D and is designed to work hand in hand with Carbide Motion.

Design your projects and create toolpaths with Carbide Create, then export the G-code and load it into Carbide Motion to turn your digital project into a virtual creation.

Click here for Carbide Create.

Carbide Motion also works with other free CNC software.

Advanced

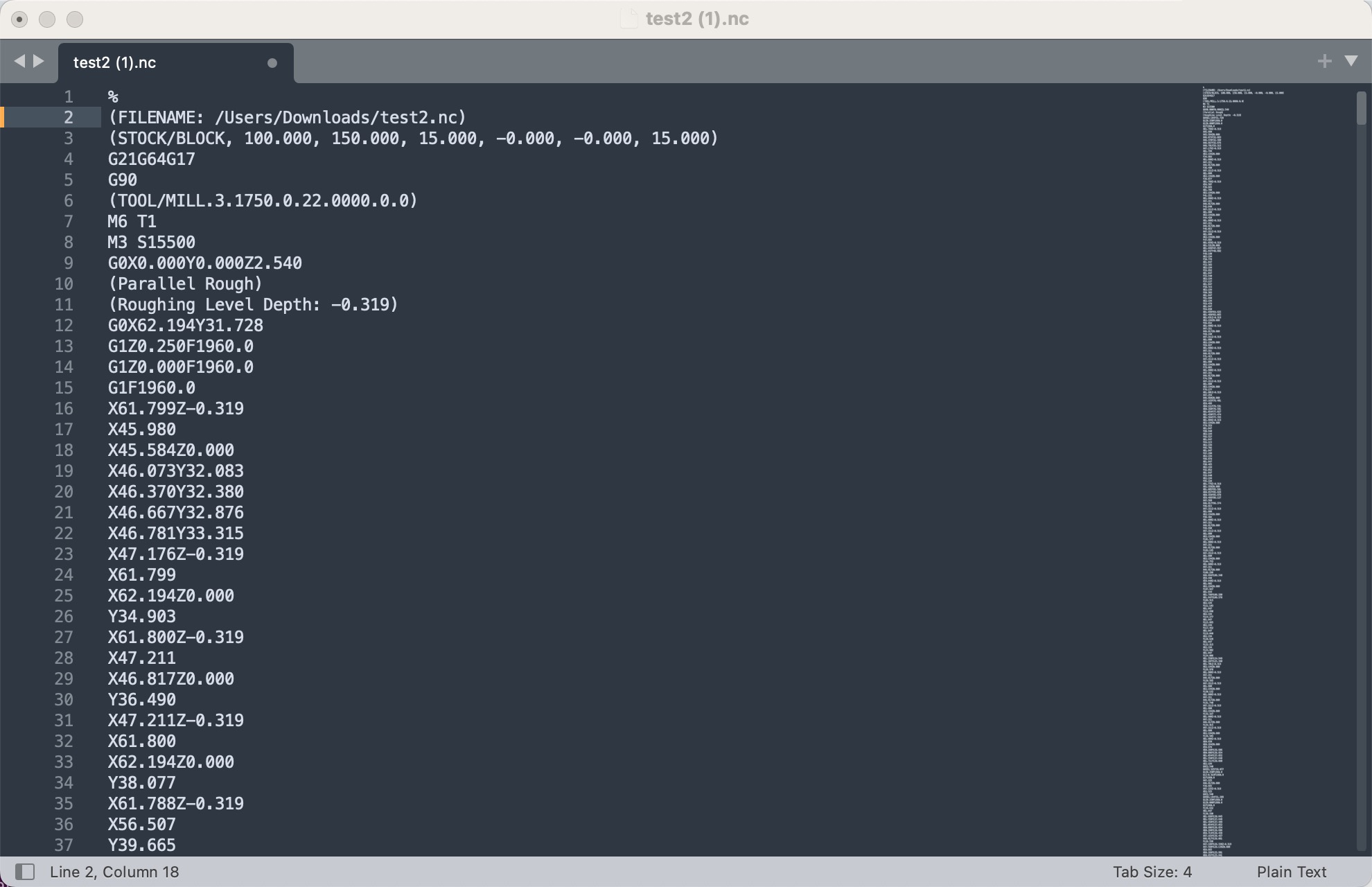

Carbide Motion loads files directly from Carbide Create so you can cut your project without generating intermediate G-code files.

If you have G-code files from other software, Carbide Motion can load and run those too. It accepts all common G-code commands.

Advanced

Some users have little snipped of G-code they like to run to automate simple tasks.

Carbide Motion has a Quick Action feature that lets you run these snippets with a single click.

Advanced

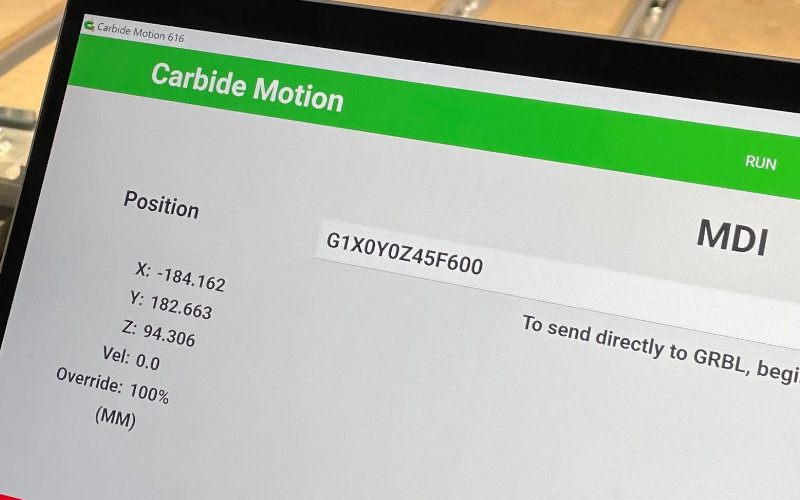

The MDI lets you send G-code directly to the machine, without having to load a file.

Not everyone needs an MDI, but if you're one of those people that need it, Carbide Motion has you covered.

Carbide Motion is included with all Carbide 3D machines.

Sorry, Carbide Motion is only available for Shapeoko and Nomad machines.

Carbide Motion runs only on Mac and Windows computers.

No, Carbide Motion runs locally on your machine, it's not a cloud application.

Yes, we've got lots of customers using Carbide Motion with Vectric V-carve or Vectric Aspire. We do recommend that users start with Carbide Create since it's included with every machine so we're able to provide support for it.

Yes, Carbide Motion works with G-code from Fusion 360.

We'll keep you up to date on new things in the world of Carbide 3D, and CNC in general.