CNC Milling vs. 3D Printing

3D Printing is one of the most important and most anticipated technologies to become widely available in years. We’ve had a commercial-grade 3D printer for a long time now and we’re still a little amazed every time we use it. That being said, it’s still a technology with lots of limitations:

- It works with relatively few materials

- It’s not that fast

- The quality is determined by the technology – you can’t make it better

- These all happen to be limitations that CNC milling does not have.

3D Printers work with very few materials

For a given 3D printer, it will only work with a few, or maybe only a single, material. For the low-cost printers this is PLA plastic, or a similar material. If you don’t care about the material, or you happen to want these, then a limited selection is OK. For everyone else, CNC milling machines provide an alternative.

CNC mills can work with almost any material you can imagine – plastic, metal, wood, wax, etc. If you’re making a prototype then you can likely use the exact material you’ll be using in production. If you’re machining the final product directly then you can imagine how complete freedom to choose the materials you use would be useful.

3D Printing is not that fast

3D printing builds objects up from nothing, layer by layer. The speed that the material can be added is defined by the machine itself and there’s not much you can do the speed it up.

Generally speaking, milling machines can remove material faster than a 3D printer can add it. This means that it’s frequently more efficient to start with a block of material and remove some of it to make your part rather than starting from nothing and building it up.

You can’t change the quality

The quality from a 3D printer is determined by the height of the build layers mentioned above- smaller layers give better quality but take more time. Larger layers are faster. In general, a 3D printer cannot vary the layer height too much so you cannot change the quality too much. It is what it is.

CNC Mills can trade quality for speed to a much greater degree. Want a part with a perfect finish? Have it spend more time going back and forth over the surface. Want a rough part quickly? No problem.

Here’s the really great part about a mill – you can change the quality on different areas of the part. If you have a section that needs to be perfect, tell the machine to spend more time in that region. If you don’t care about the finish on the back side of the part you can tell the machine to do that quickly.

Why would I want a 3D printer then?

There are two areas where 3D printing really excels:

- They can make shapes that are impossible to make any other way

- They require almost no skill to operate

That first one is important but it’s the second one that’s critical – 3D printing is fundamentally easier than CNC milling. That was one of the core problems that we set out to solve, and we think that our machines really close the ease-of-use gap between 3D printing and CNC milling.

So what do I need, a 3D printer or a CNC mill?

How about both? For all of the problems above, 3D printing is an amazing technology and a well-equipped shop will find lots of uses for both a CNC mill and a 3D printer.

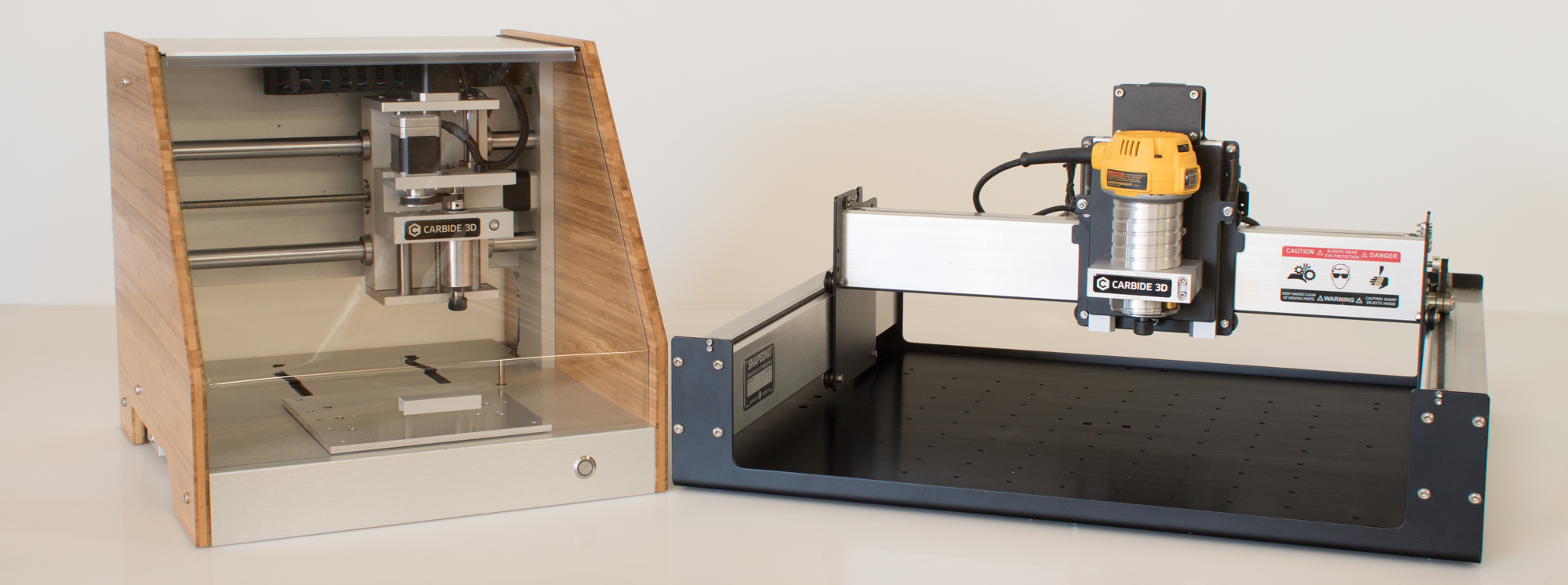

We make the Nomad Pro Desktop CNC mill. When we started this company we were inspired by what the early 3D printers brought to the desktop. We designed the Nomad Pro to sit right beside a 3D printer on your desktop.