The data that we've been able to collect from users over the past few months has made something very clear, almost all machine disconnects we see today are caused by static electricity from the vacuum hoses. I'm sure that some will find that to be a controversial statement, but it's based on the best data we have in working through problems that real customers are having.

Figuring out anything related to static discharge is very difficult because it depends on the environment, the wiring in your shop, the exact arrangement of the machine, and everything that interacts with it electrically.

Several of us at Carbide 3D have been shocked by touching the vacuum hoses in our shops, both in California and Illinois, but we have never had a disconnect. This serves as a reminder of another fact, most users will never have a disconnect problem, even with an ungrounded hose. (Setting the potential shocks aside)

If you are having a disconnect problem, there's no getting around the fact that step one is to ground the vacuum hose that goes into the machine. Doing so may not be the only remedy required, or the sole cause of trouble, but's the most likely.

Diagnosing the problem

If you have a persistent disconnection problem, here are a few things to try:

- Run the job without the router turned on, but leave the vacuum or dust collector turned off. If you get a disconnect then it could be noise coming through your AC line.

- Run the job with the router turned off, but with the vacuum turned on. If you get a disconnect, it's likely the static discharge from the vacuum. It's time to ground that hose.

Option 1, The Right Way

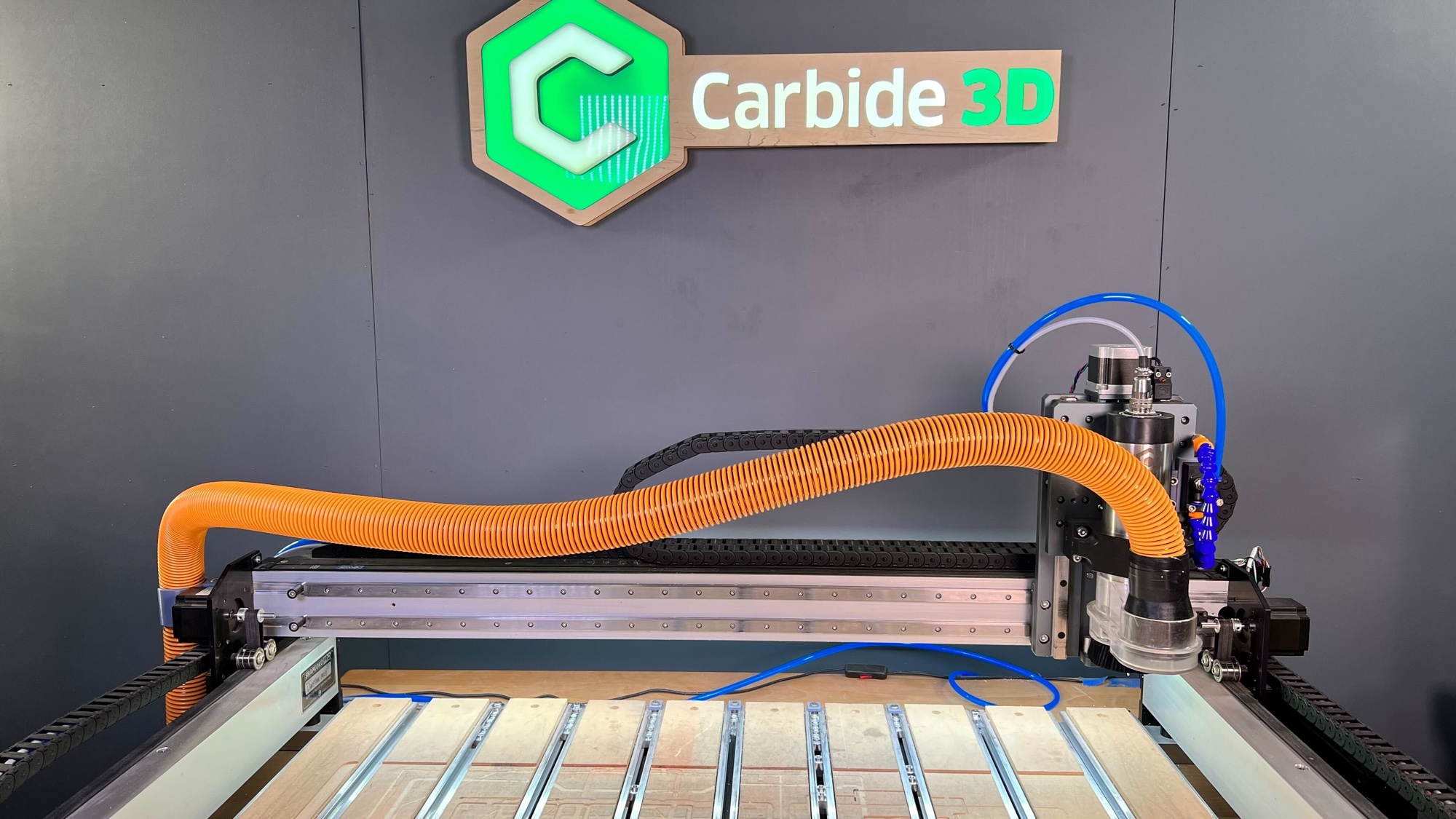

The right way to ground your vacuum hose is to buy a conductive or anti-static hose to go from Sweepy to your vacuum or dust separator. A proper anti-static hose will usually have a wire embedded in it, and have some conductive material mixed in with whatever plastic it's made from to allow the electrical charge to drain to the wire.

Once you have an anti-static hose, you need to either connect the embedded wire to the machine frame, or wrap some bare wire around the hose and then ground that hose to the machine frame.

We don't have a specific model to recommend, but here are a few that look good:

- https://www.rockler.com/rockler-dust-right-2-1-2-in-anti-static-dust-hose

- https://www.amazon.com/Cen-Tec-Systems-94434-Antistatic-Universal/dp/B07Q7SSTPX (Not 2.5")

- https://www.woodcraft.com/products/flexaust-2-1-2-anti-static-clear-dust-collection-hose-flexaust

- https://biscoair.com/heavy-duty-flexible-hose-with-grounding-wire/

We'd prefer the fourth option above, because it gives you a wire that can be directly grounded to the machine frame.

Option 2, It Seems to Work

This is something we've seen from users who say it works well. A couple of us at Carbide are electrical engineers, so it makes us a little uneasy to recommend this approach, but there's no denying the success that users have had.

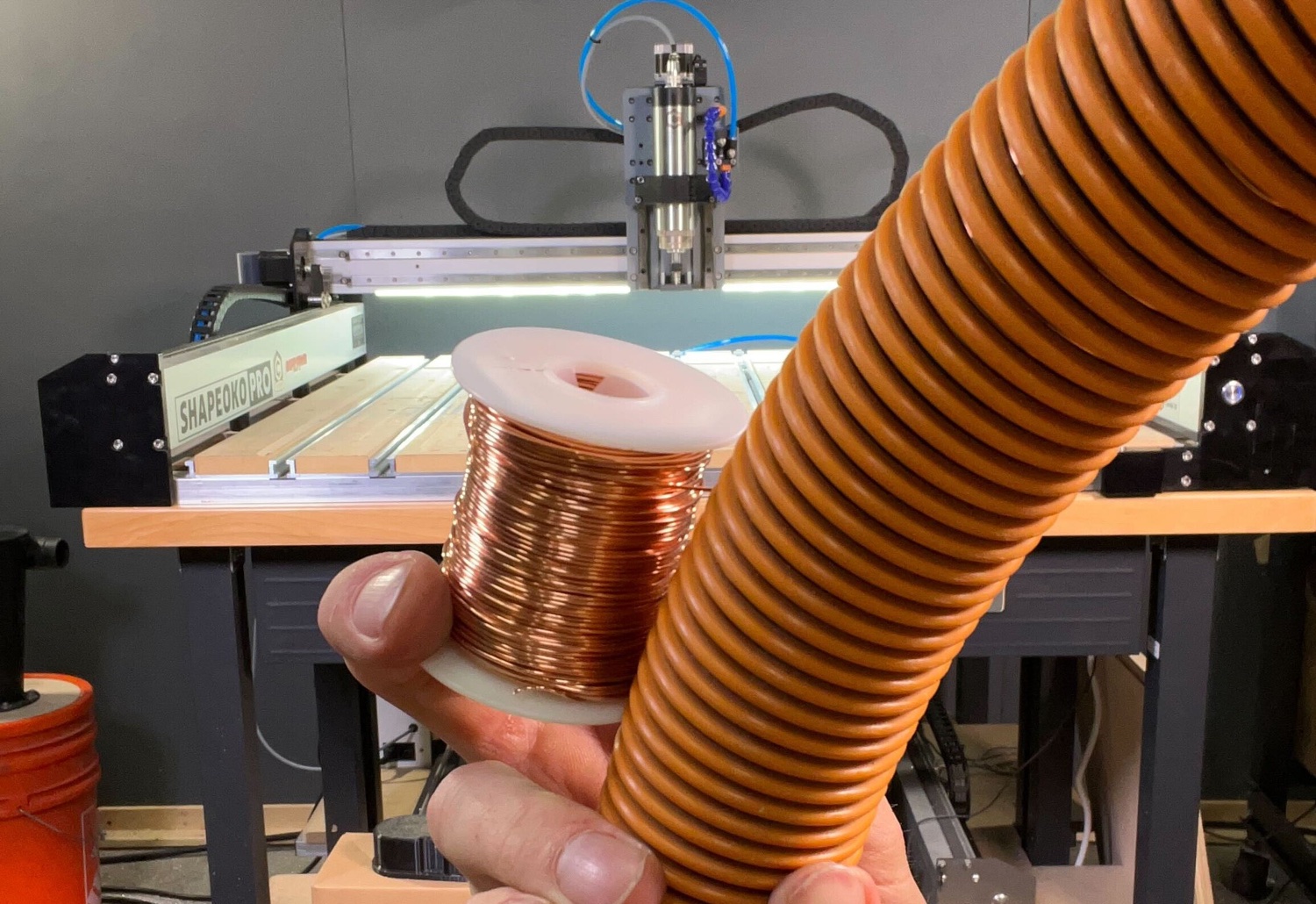

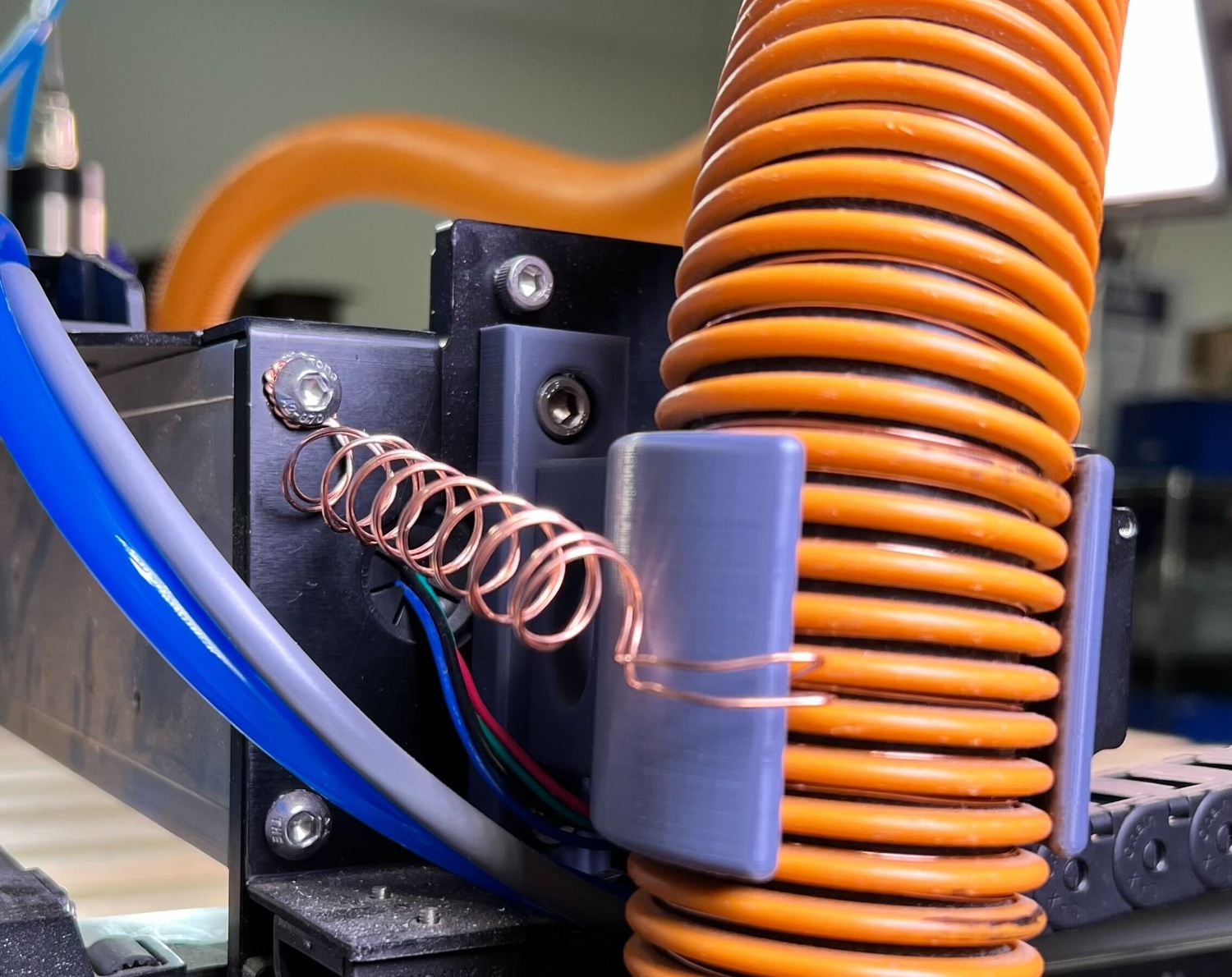

Take a length of bare copper wire and wrap it around the spiral in your vacuum hose, from Sweepy to your vacuum or dust separator. Leave enough slack so that you can ground the wire on your machine frame. You may need to take some electrical tape to wrap around the hose every 6 inches or so to keep the wire in place.

Why does this make us uneasy? Because there's no electrical connection from the inner section of the hose to the wire, as there would be with an anti-static hose. That said, it's the static charge on the outside of the hose that's more likely to cause trouble so that may not be a big deal.

We tried it on one of our hoses in the shop, just to see how easy it would be. We used some bare 20 gauge copper wire from McMaster-Carr and then spent 15 minutes wrapping it. If you choose to try this, be sure to get bare wire with no insulation at all, either plastic or enamel.

We never had a disconnect problem before, so we can't speak to the benefits, but we haven't been shocked by the hose after wrapping it, so that's a win. It's also much cheaper that a real anti-static hose.

Conclusion

We're happy to help work through any problems that you're having, disconnects or otherwise. Remember, [CNC dust collection is critical to the proper operation of your machine so it's worth taking the time to get it right.