Like most of our product development, this is not something we planned to do, it just kind of happened… again. We saw the completed Shapeoko Pro and we fell in love. We couldn't unsee it. We wanted more. So we did the only logical thing we could do, we made the Shapeoko 4.

Big picture, the Shapeoko 4 takes most of the upgrades on the Shapeoko Pro and combines them with the Shapeoko 3. Or, maybe more accurately, the Shapeoko 4 removes the rails and BitSetter from the Shapeoko Pro to make a more affordable machine.

Either way you look at it, here's what we changed going from Shapeoko 3 to Shapeoko 4:

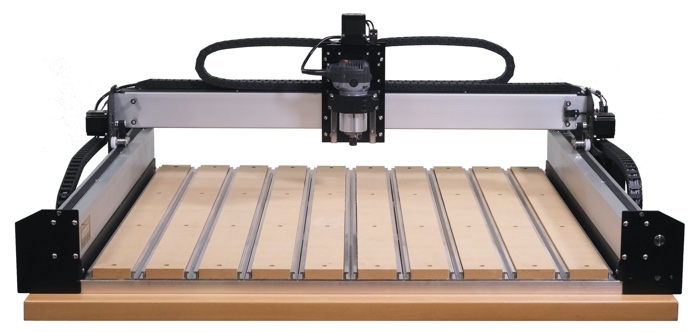

The Hybrid Table is really the heart of the machine. It's a stable and rigid foundation made up of a grid of custom extrusions that are precision-machined in-house on our growing fleet of machining centers. You can't build the kind of machine that we want to make on a bad foundation. The Hybrid table is the best foundation we can make without going totally overboard on cost and shipping.

Need flexible workholding? The Hybrid Table has t-slots built-in and a dozen Teez-nutz are included. Add our Tiger Claw or Gator Tooth clamps and you can hold just about anything.

Want to surface your MDF to get a totally flat surface? The MDF sits proud of the aluminum structure so you've got clearance to take a skim cut.

Want to add threaded inserts or other features to the MDF? No problem, drill the MDF in-place or take it out and add them.

Need replacement MDF slats? They're easy to cut by the dozen on a table-saw in a few minutes.

We all have our favorite part of the Shapeoko 4 but the Hybrid Table is my favorite part by far.

The other big function of the Hybrid Table is to fully support the Y extrusions front-to-back. Our custom extrusions already over-designed and would be fine even on a much bigger machine but the added support takes away any potential for flex and, more importantly, ties the entire structure together.

The Shapeoko v-wheels have been unchanged for a long time even though the Shapeoko 3 bears no resemblance to the original Shapeoko 1 or 2. It was time for a change based on all we've learned over the past years.

We took a look at the existing v-wheels to see what we could improve and came up with a number of changes to add strength and rigidity. Our testing has shown them to be roughly twice as rigid on the X axis as the previous design.

In addition to the better performance, they're a little larger in diameter so they should also be much more durable.

(Anticipating a question: They're a little larger in diameter so they won't work on the Shapeoko 3)

The new Carbide Motion V3.0 PCB from the Pro will also be used for Shapeoko 4. It's got better ESD/EMI protection, new connectors and a new wiring harness, making my least-favorite part of assembly much faster.

The Shapeoko 4 includes the new 65mm mount that we designed for the Shapeoko Pro. It's thicker for a more rigid grip on the router and it just looks cooler.

An important thing to note is that it's only a 65mm mount so it'll fit our Carbide Compact Router, the Makita trim router or a 65mm VFD spindle but NOT a DeWalt trim router.

DeWalt seems to be dropping in popularity and they're the only 69mm router so it makes sense for us to make a really good 65mm mount instead of a combo model. And on a side note, when we sold the DeWalt router, we had more failures with that model so it's not one we recommend any more.

We're using 15mm belts on the Shapeoko 4, the same ones on the Shapeoko Pro. Shapeoko 3 used 9mm so you can expect these new belts to be roughly 65% stiffer.

A major focus of the Pro was to make assembly and the out-of-box experience better. The feedback we've gotten on the Pro tells us that we made great progress. A few Pros shipped before the assembly video got posted and users were able to put it together with no instructions at all.

The Shapeoko 4 should go together almost like the Pro and the assembly process should be a big upgrade from the 3.

We have heard from Pro users that they don't like the machine shipped in two boxes but that's going to be unavoidable. Shapeoko 4 and Pro are big and heavy and UPS and Fedex won't take them in a single box.

If we were able to ship in a single box, we'd hate to see what the box would look like when you got a Shapeoko 4 delivered.

According to Edward and Winston, and this is wholly and completely subjective, the Shapeoko 4 gets you to 80% of the Shapeoko Pro. It's a much more capable machine than the Shapeoko 3 and it's much more convenient machine because of the workholding from the Hybrid Table.

It's capable of stalling the trim router so we think it's a very well balanced machine.

Can I upgrade a Shapeoko 3 to a Shapeoko 4? Unfortunately no. If there are any shared parts between the machines, I can't think of them. Like the Pro, it's all-new.

Can I upgrade from a Shapeoko 4 to a Shapeoko Pro? Probably not. We've done the preliminary math and it's a lot of cost. The cost is enough that the better scenario is to sell the Shapeoko 4 and get a Shapeoko Pro if you're looking to upgrade.

Can I upgrade from a Shapeoko 4 to a larger Shapeoko 4? Probably not. An upgrade would require almost the entire machine to be replaced except for the Z axis and electronics so it's not really a cost-effective way to go.

So, if you don't own a Shapeoko yet, should you buy the 4 or the Pro? It really depends on how much the price difference matters to you. For the XXL, the price difference is around $500 and the Pro includes a $120 BitSetter.

Personally, I'd feel pretty good running either machine hard. If I was going to put it in my garage, I'd prefer the Shapeoko 4 because the v-wheels are lower maintenance (no oiling, not potential for rust, etc.). There's not much to go wrong over time.

If I was going to run it all day, maybe I'd prefer the Pro.

You can't go wrong with either machine.

First, this really is a very new product. Because we're able to leverage a lot of the parts and process from Shapeoko Pro, we have been able to get this ready for production quicker than anything we've ever made before.

Second, most of our vendors have been extremely unreliable for the past 6 months and we're at the point that we can't count on anything that we haven't taken delivery of. We now have everything we need to go into production that could have been a big risk so we're announcing today.

All three sizes of Shapeoko 4 are in production and we're planning to list them for sale on May 1st.

We'll be doing weekly drops and only putting the quantity that we can ship in a week or two in stock. We're hoping that we'll never build a massive backlog with this plan like we did when we announced the Shapeoko Pro.

We'll keep you up to date on new things in the world of Carbide 3D, and CNC in general.