Nomad Pro in Detail

The Nomad 883 broke new ground in desktop CNC machines when it was released in 2014. The Nomad was the first machine in its class to be delivered ready-to-run, with everything included. With the Nomad 3, we've taken it all to a whole new level.

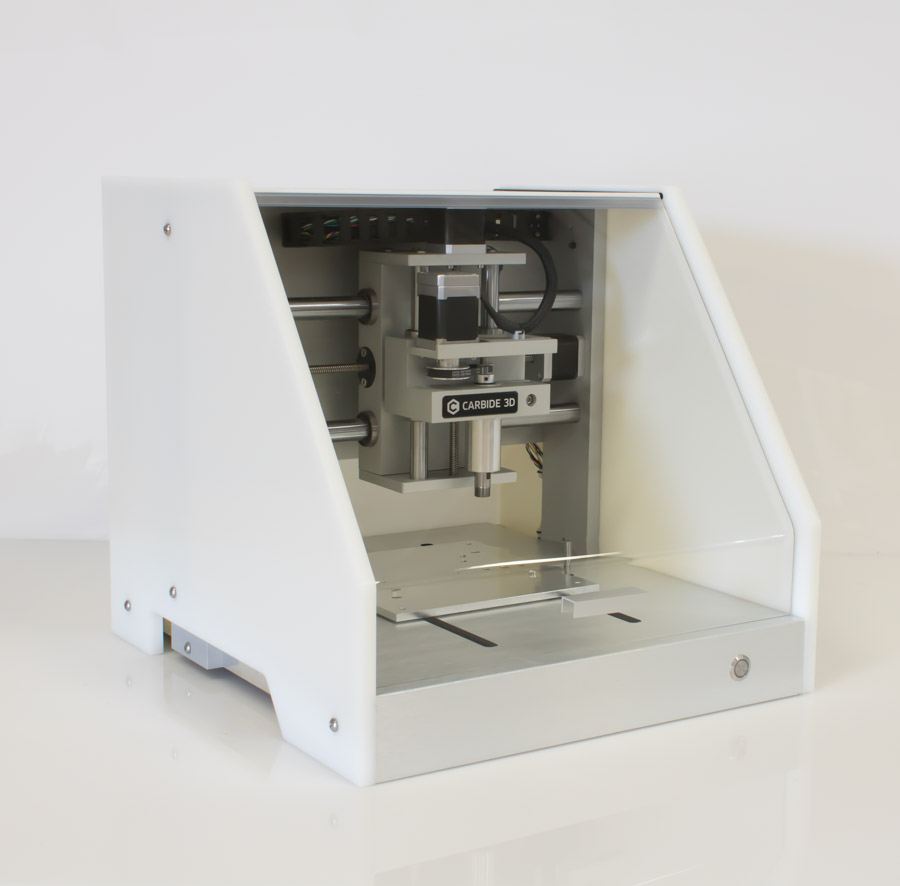

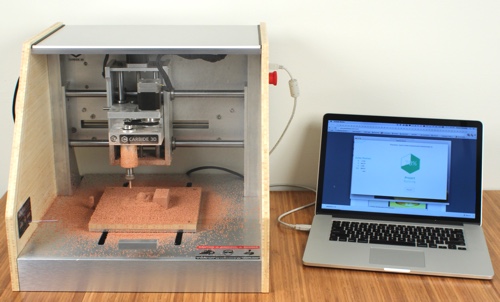

Fully Enclosed

The Nomad 883 comes fully enclosed in either HDPE or Bamboo to contain both dust and noise.

With the enclosure closed, it's possible to put the Nomad in your home or office and not worry about making a mess. A small shop vac is all you need.

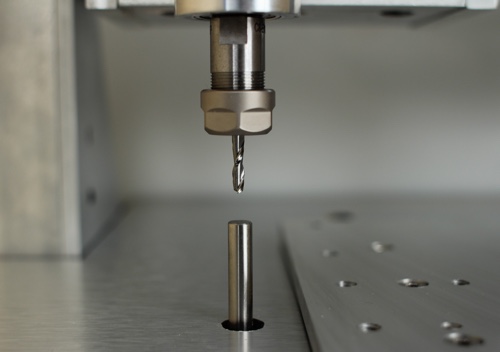

Tool Length Measurement

Calibrating tool length is always a pain on a desktop CNC machine because they lack the automation found in big industrial machines.

For the Nomad, we designed an accurate and easy way to automatically measure the tool length before cutting anything. It's completely integrated into our machine and software so it's all done during the cutting process.

Custom Made Spindle

We designed our own spindle specifically for desktop machining. The quick specs:

- 10,000 RPM

- Sealed ball bearings

- ER-11 Collet

- Brushless DC motor

- Custom drive electronics

For the Nomad 883 Pro, we've reworked the spindle electronics and firmware to make it smoother and more reliable.

It remains the most durable and quiet spindle you'll find on a desktop machine.

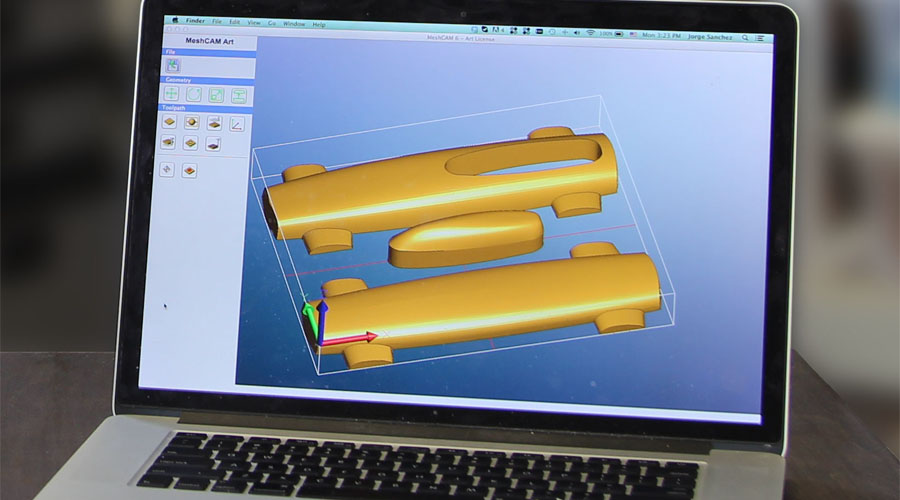

3D CAM Included

The Nomad 883 Pro includes MeshCAM, easy-to-use 3D CAM software.

MeshCAM takes an standard STL file from your CAD program and generates a toolpath with minimal input from you. If there's an easier way to generate a 3D toolpath, we're not aware of it.

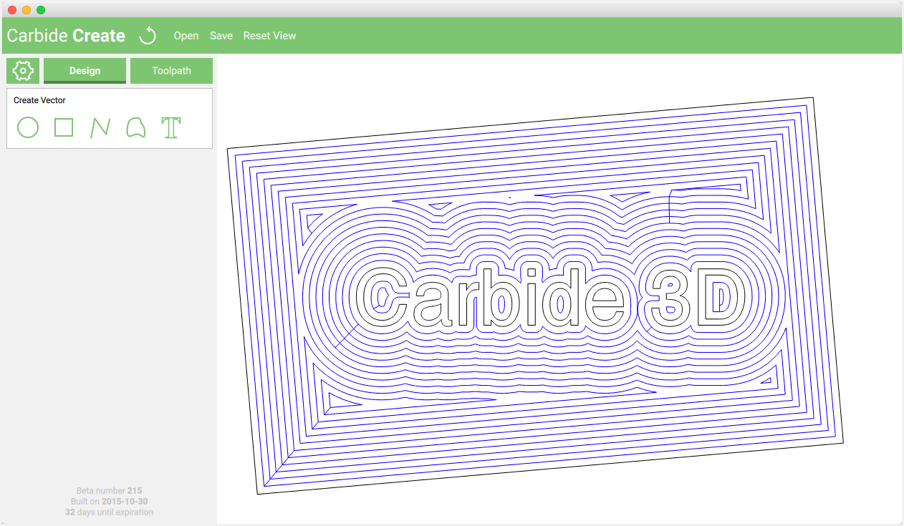

2D CAD /CAM Included

The Nomad 883 Pro also comes with Carbide Create, our own 2D CAD/CAM software.

Draw your own parts in Carbide Create, or import a DXF file from your CAD program and use it to create the toolpaths.

Carbide Create is easy enough for beginners to CNC, but powerful enough that you won't outgrow it. We wrote it from scratch for our machines, we didn't license it from another company.

Carbide Create is downloaded and run from your own machine, it's not cloud software that can be insecure and unavailable.

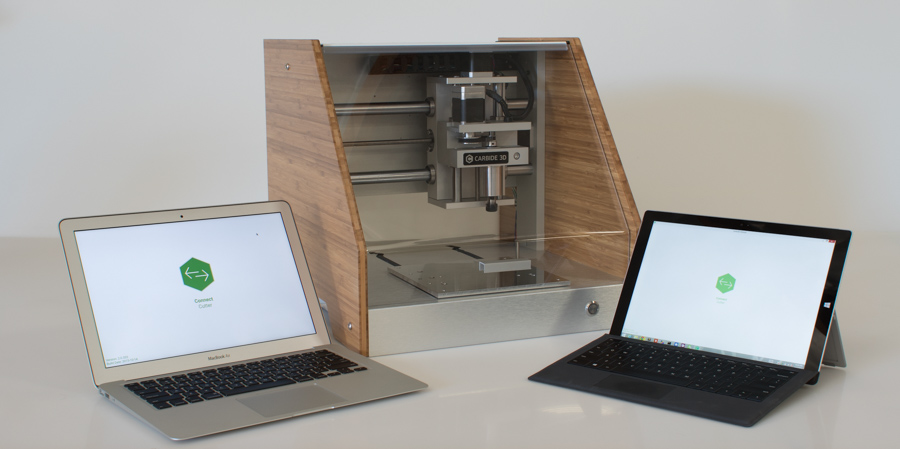

Support for Windows and Mac

We support both Windows and Mac for all of our software.

We think you should be able to use whatever computer you want, and we do everything we can to support them both equally.

Made in California

Most of our custom parts are made within a hour of us Southern California. We get a much better product by being able to walk into a shop and talk to the actual people making our parts.

You can't get this level of quality buying parts from a factory in China.

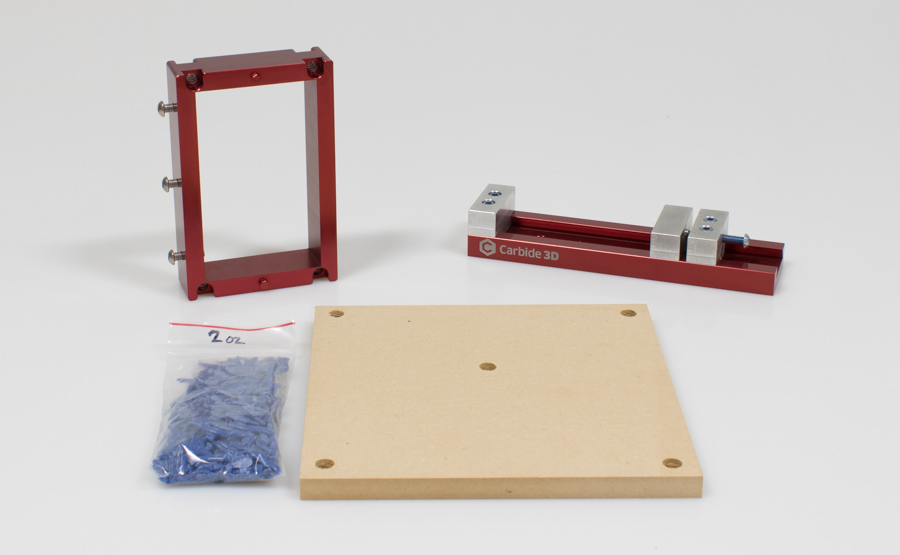

Built-in Fixture Options

One of the most difficult things about machining is figuring out how to hold the parts you're trying to machine, and that was something we wanted to tackle from the start.

We make a range of fixturing accessories that are built to connect right to the machine.

- Low profile vise

- Flip jig

- Wasteboards

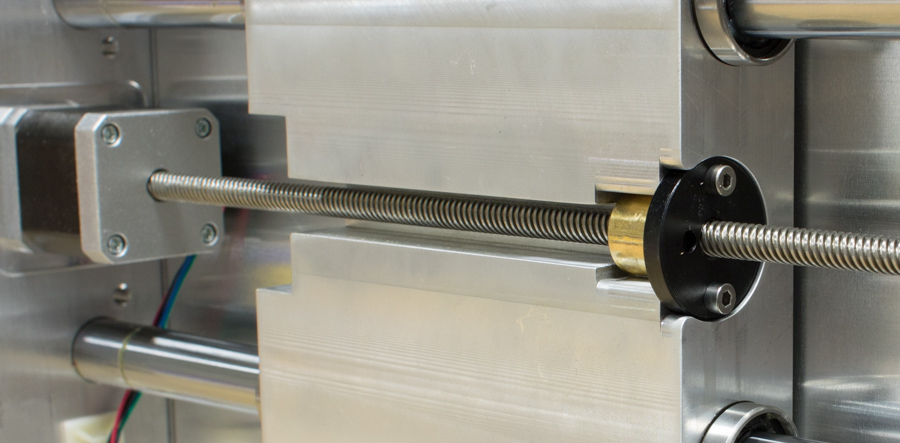

Anti-Backlash Lead Screws

To make the Nomad 883 Pro as accurate as possible, we use leadscrews with anti-backlash nuts for the X and Y axis.

We use a very fast pitch to make sure that the Nomad 883 Pro is capable of high speeds for efficient 3D machining.

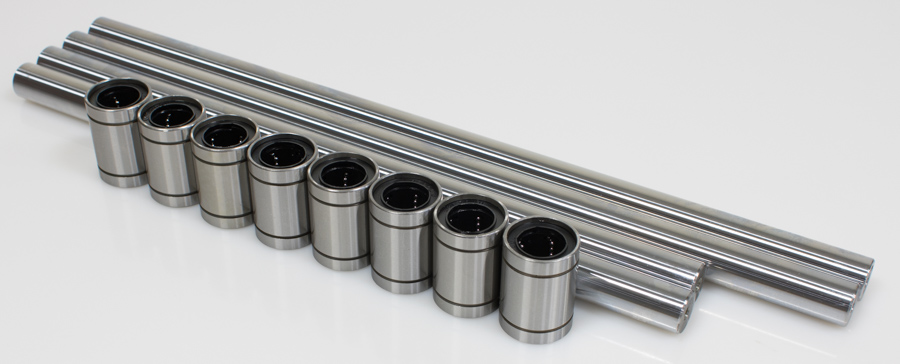

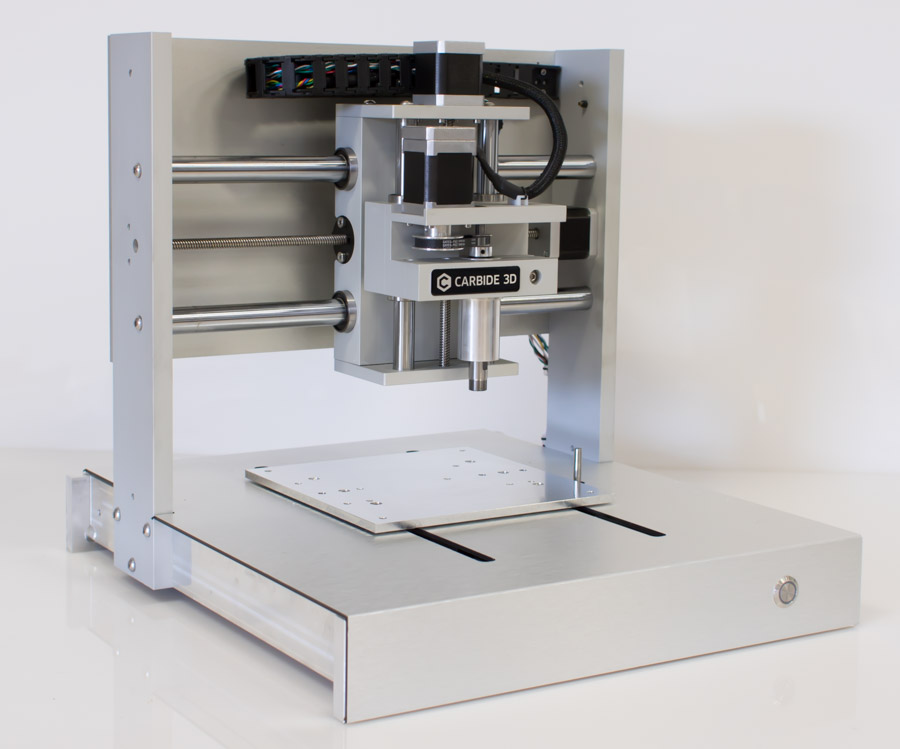

20mm Linear Bearings

For our X and Y axis, we use a 20mm linear bearing that is over 50% stiffer than the 16mm bearings we used before.

We also upgraded the Z axis to 16mm from 12mm to make sure that the X, Y, and Z are all well-matched.

Fits on Your Desktop

The Nomad 883 Pro has a 20 x 20 inch footprint so it fits on almost any common desktop or bench top.

For the Pro, we made a number of changes to slim down the design without changing the cutting area.

Precision Machined Frame

The frame begins as a bunch of aluminum blocks in our shop, where it is turned into the supreme CNC masterpiece that is the Nomad 883 Pro.

That's putting it on a little thick, but we're pretty sure that nobody pays more attention to the fit and finish of their desktop CNC machine than we do.

After machining, we bead blast and powder coat external parts. We want to make sure the machine looks good and is well-protected.

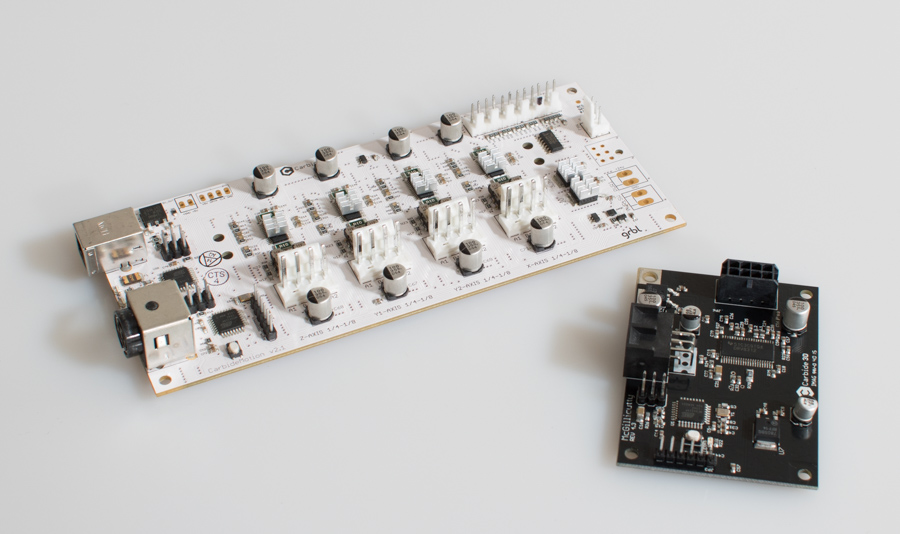

Custom Electronics

The Nomad 883 Pro electronics are all new, and like the previous versions, designed by us specifically for our machines.

We do everything we can to increase reliability and to manage the heat from the motor drivers. We've literally argued over individual PCB traces but the results speak for themselves.

One Supplier for all Your Needs

The Nomad works with all standard cutters and materials, there's nothing proprietary here so you can use your favorite brands without any trouble.

For those who want to look for additional suppliers, we have an online store full of cutters and materials that we know will work well with the Nomad.

We buy everything we can from local vendors, we don't just order a pallet of material from overseas.

Everything you need in one box

Nomad Pro comes with everything you need to get started with CNC machining with nothing more to buy.