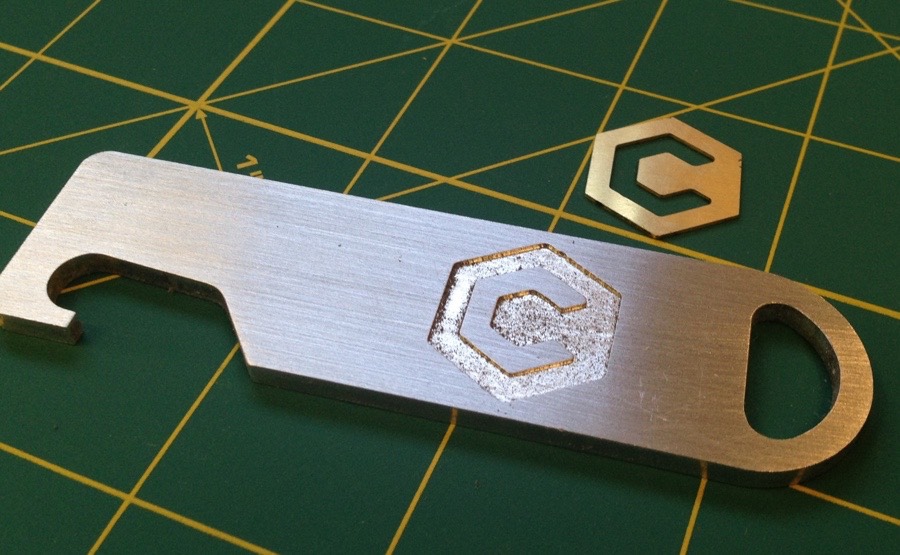

Bottle Opener with Brass Inlay

Our first Nomad project in metal

This was one of the first metal parts we cut on the Nomad 883. We wanted to show that metal cutting was possible and that the machine was accurate enough to cut multiple parts that need to fit together.

The inlay was glued in using JB Weld and then finish sanded to make the brass and aluminum perfectly flat.

When you hold the bottle opener in your hand, it’s almost impossible to feel the transition from aluminum to brass.