Awesome!!! Quick fix!!!! Thank you so much! Your customer service is 2nd to none, incredible.

Chad B.

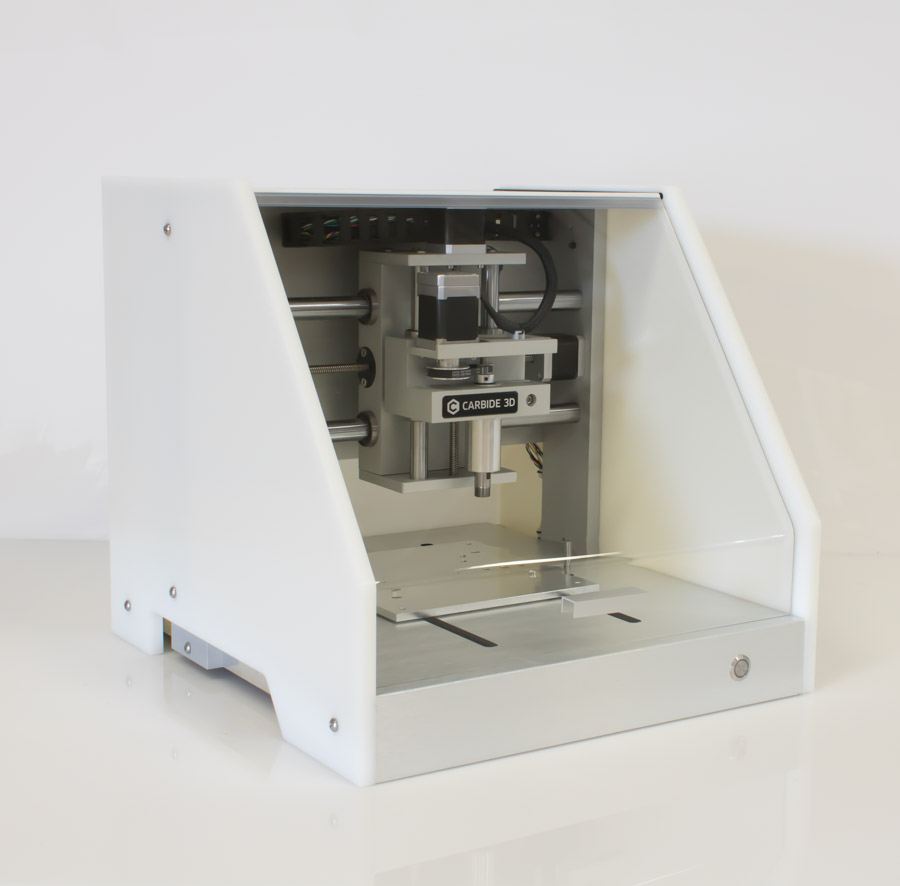

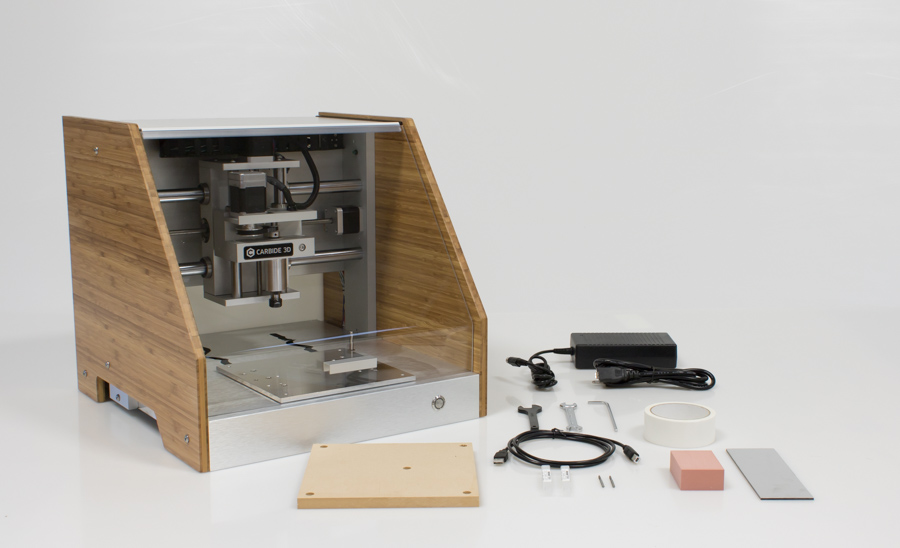

A fully integrated, ready-to-run desktop CNC mill that's at home in any environment

CNC machines are capable of making beautiful parts– if you know how to use them.

The Nomad 883 Pro is not just another desktop CNC machine, we designed it to make CNC machining something that normal people can do.

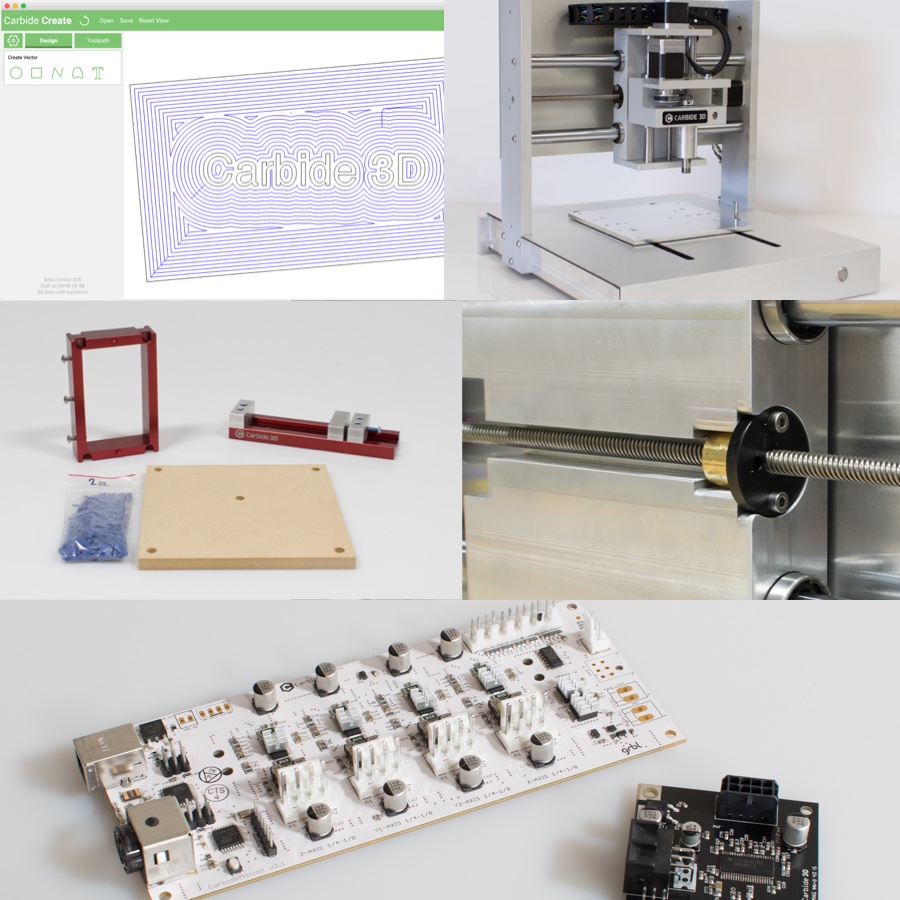

All the complexity of traditional CNC machines is handled in the background.

This is only possible because of our highly-integrated hardware and software, something that isn’t possible if you have to find your own software to run the machine.

While our Shapeoko CNC Router and Shapeoko HDM have a large cutting area with a lot of power, the Nomad is built to take up minimal space and cut a wide variety of materials without making a mess.

The Nomad 883 Pro includes all the hardware and software you need to take your 3D file and make a part. We’ve taken the uncertainty and frustration out of the equation, just open the box and get started.

Whatever materials you need to work in, whatever CAD program you use, the Nomad can do it.

Whether you work in wax or directly in metal, the Nomad is capable of the fine detail you need.

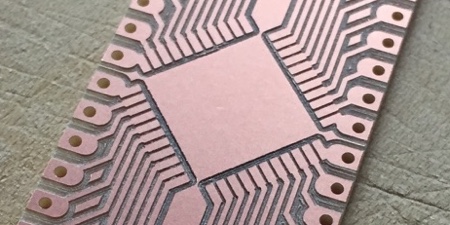

The Nomad has the precision to do PCB milling with ease, even with SMT components.

Plastic machines really well on the Nomad: HDPE, Delrin, acrylic, polycarbonate, and more.

Any kind of wood is suitable for the Nomad, from pine to maple, oak, or the even more exotic species.

Soft metals, like aluminum and brass up to .25" thick cut well on the Nomad.

The Nomads spindle is fast and has low run out- it's perfect for engraving jobs.

The Nomad is accurate enough to cut inlays and pockets that fit together perfectly.

You're not limited to simple 2D cuts. The Nomad can do complex, flowing organic shapes with ease.

Is it for you? Ask us! There's nothing we enjoy more than talking about CNC machines. We'd love to talk to you about your application.

The Nomad 883 Pros small footprint means that even fully enclosed, it takes up about as much space as an inkjet printer or desktop 3D printer. Our desktop CNC turns your desktop into a workshop.

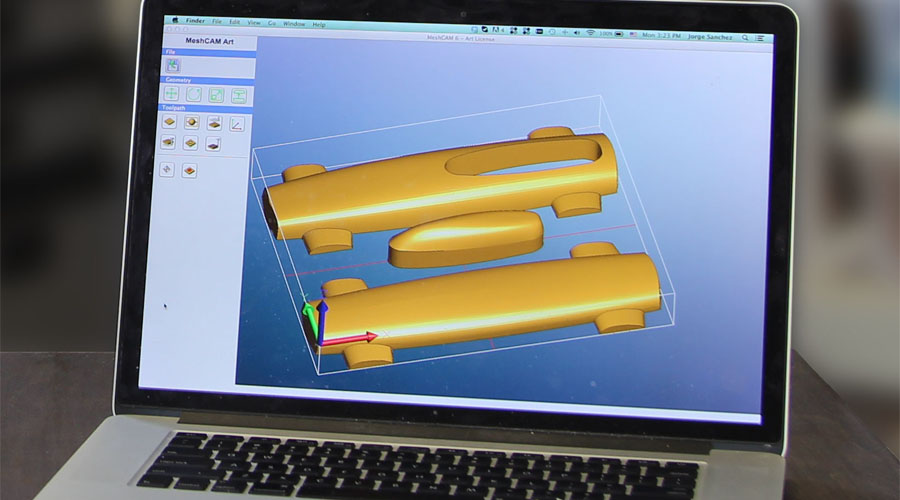

A CNC machine is not worth much without the software to drive it, and most of them, don't come with any software to help you complete your projects. The Nomad 883 Pro comes with all the software you need to make parts:

If you have a favorite CAM program and work flow The Nomad 883 will work with it. Carbide Motion can read gcode from any CAM program so you’ll never be locked into proprietary software.

MeshCAM, Carbide Create and Carbide Motion are cross-platform so you can run them on a Windows or Mac computer.

What does that mean for you?

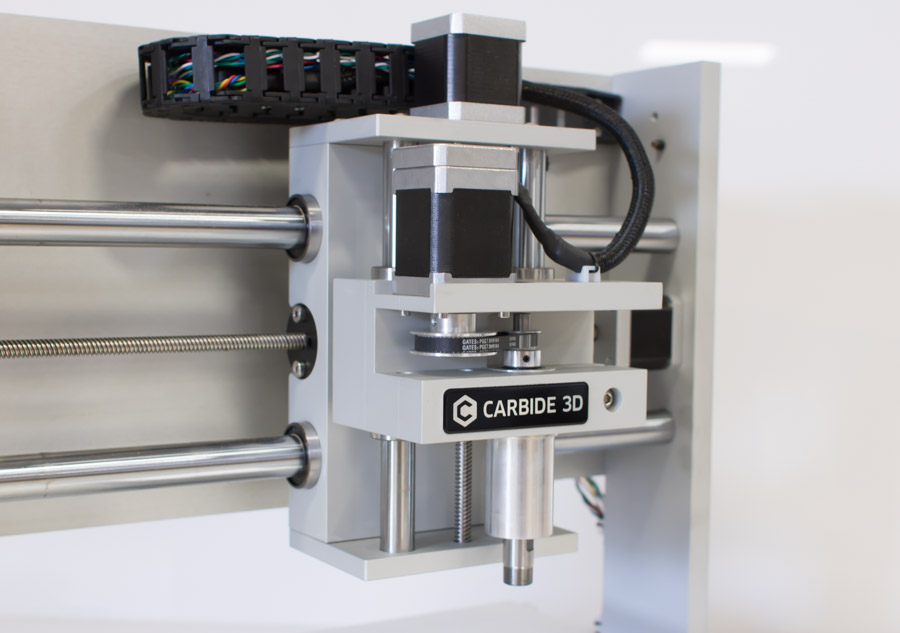

The Nomad 883 Pro has a durable and quiet spindle that’s capable of cutting a variety of materials without being so loud that it drives you out of the room.

The Nomad 883 was named "Best CNC Mill" by Make: Magazine in their "Ultimate Guide to Desktop Fabrication 2016" based on testing by 16 industry experts.

The Nomad 883 Pro is ready to go the first time you power it on.

It includes:

The only thing you need is a Mac or Windows computer.

That's just a quick introduction to The Nomad 883 but its full of other great features.

We've spent our careers in product design and manufacturing. We’ve been on the hook to turn around prototypes and concept models in record time so we know what it takes to get that done. The Nomad 883 Pro was designed to be the machine that we wanted years ago, during those late nights and long weekends. We know that you don’t want to spend weeks learning a new tool. We know you just want to get your parts made quickly.

The Nomad 883 Pro was designed to help you complete your project now, not to become its own project.

Awesome!!! Quick fix!!!! Thank you so much! Your customer service is 2nd to none, incredible.

Chad B.

Thank you so much for your assistance. I have a few friends interested in your machines I will definitely recommend you guys to them all. You guys are awesome.

Eric B.

I’ve been cncing with your product for a little over a year now and went through 2 upgrades. I’m very pleased with your product and you also have amazing customer service. I’ve recommended and will continue to recommend your products to others. Keep up the good work.

James M.