Shapeoko CNC Routers include everything you need to start making amazing projects to keep, give as gifts, or sell.

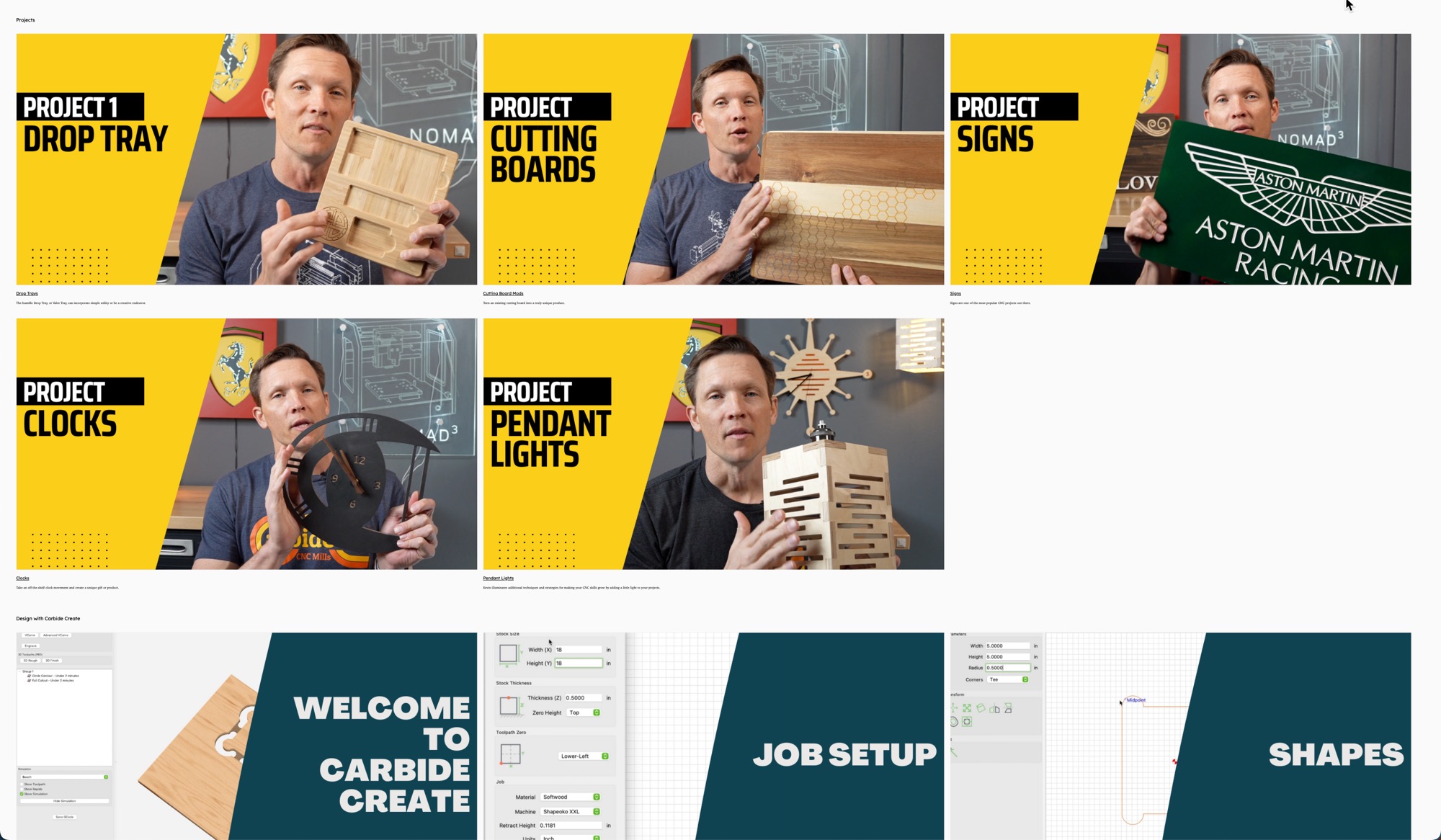

These projects were made on Shapeoko CNC routers, by actual owners.

Our range of Shapeoko CNC Routers caters to makers at every level, from passionate hobbyists working out of their garages to small businesses running production. Each model delivers professional-grade performance, scaled to fit your space and budget.

Whether you're crafting intricate wooden inlays or producing small batches of precision parts, you'll find a system that fits you.

Big, Accurate, and Powerful

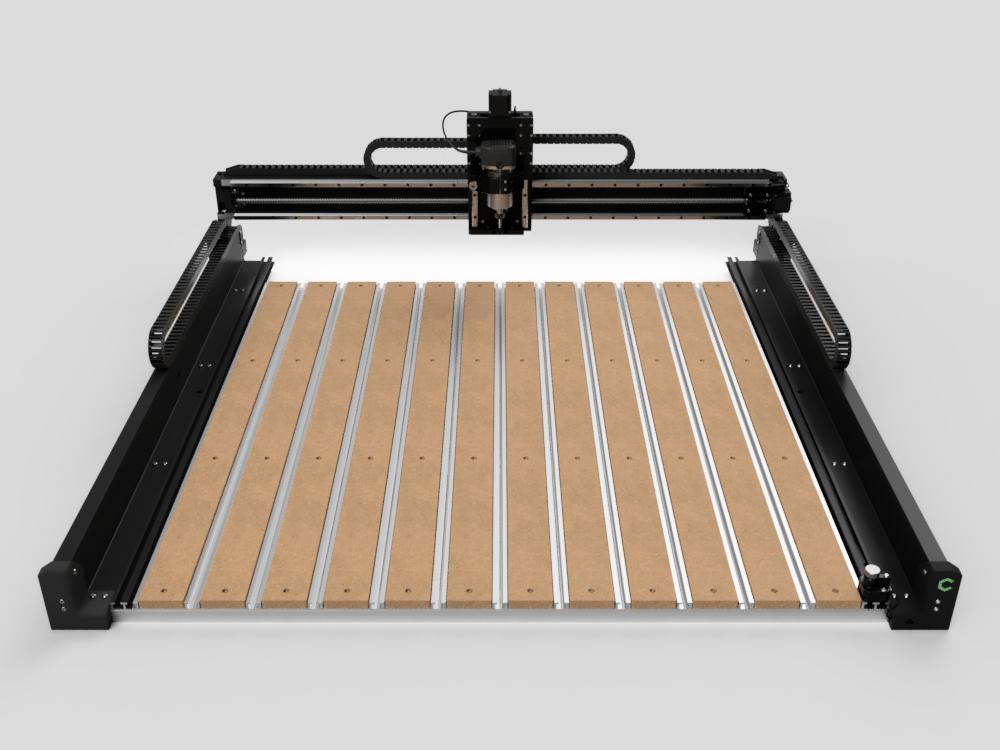

Shapeoko 5.1 Pro is our newest and largest machine.

Shapeoko 5.1 Pro is based on a ballscrew and linear rail motion system, the same motion system used on industrial CNC machines.

Shapeoko 5.1 Pro is the recommended machine for users who want maximum performance and accuracy paired with a larger cutting area.

Starting at $3200

Sizes:

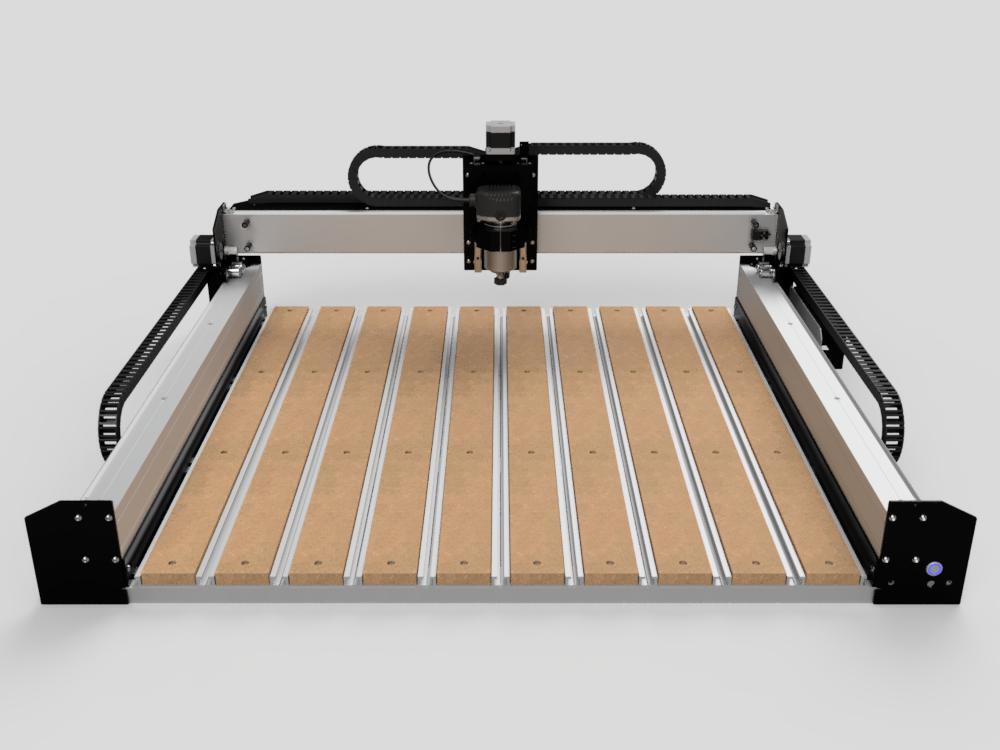

High Performance at a Lower Price

Shapeoko Pro uses linear rails and belts on every axis for increased rigidity and performance. That translates into more efficiency and better finishes compared to the Shapeoko 4.

Shapeoko Pro is a solid upgrade over the Shapeoko 4 for those looking for higher performance or plan to use it a lot.

Starting at $2400

Sizes

Perfect for Home Shops

We took the Shapeoko Pro and replaced the linear bearings with V-wheels for maximum value and minimum maintenance.

It's got 90% of the performance of Shapeoko Pro, but at a lower price, making the Shapeoko 4 an ideal machine for those just getting started in CNC.

Starting at $1800

Sizes

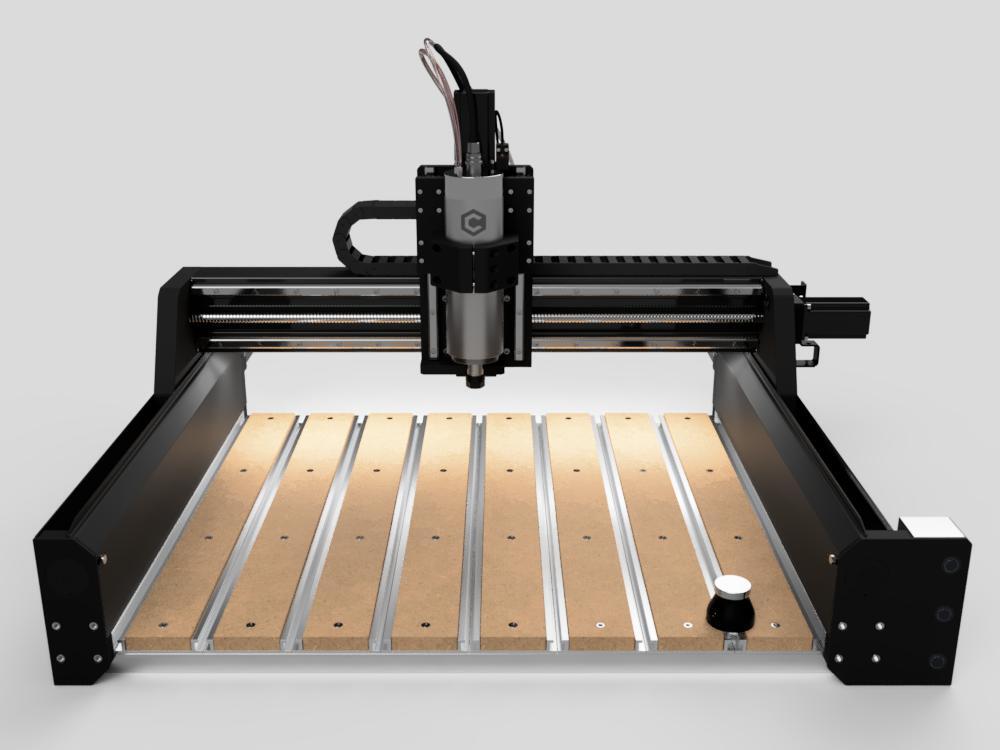

Ready for Production

Shapeoko HDM is our most powerful, most rigid machine. It's designed for demanding prototype and production work.

Shapeoko HDM ships fully assembled and ready to run, with a water-cooled spindle.

Priced at $5400

Sizes

Shapeoko was built for woodworking, but its rigid frame and powerful spindle options make it a great choice for cutting aluminum and other metals.

The video below shows a roughing toolpath in aluminum to remove material quickly.

Shapeoko is made in the USA, in our factory in Illinois. We're proud to support American manufacturing.

Shapeoko was designed to be the most capable CNC router in its class while also being the best value. Curious how we did that?

Learn what makes Shapeoko differentIt's tough to pick only a few reasons to choose Shapeoko, but here are some of the top reasons our customers tell us they chose Shapeoko.

1. Rigid and Accurate

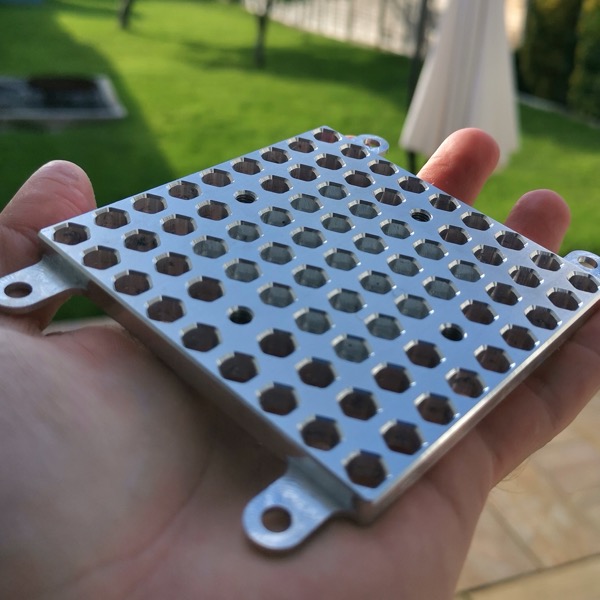

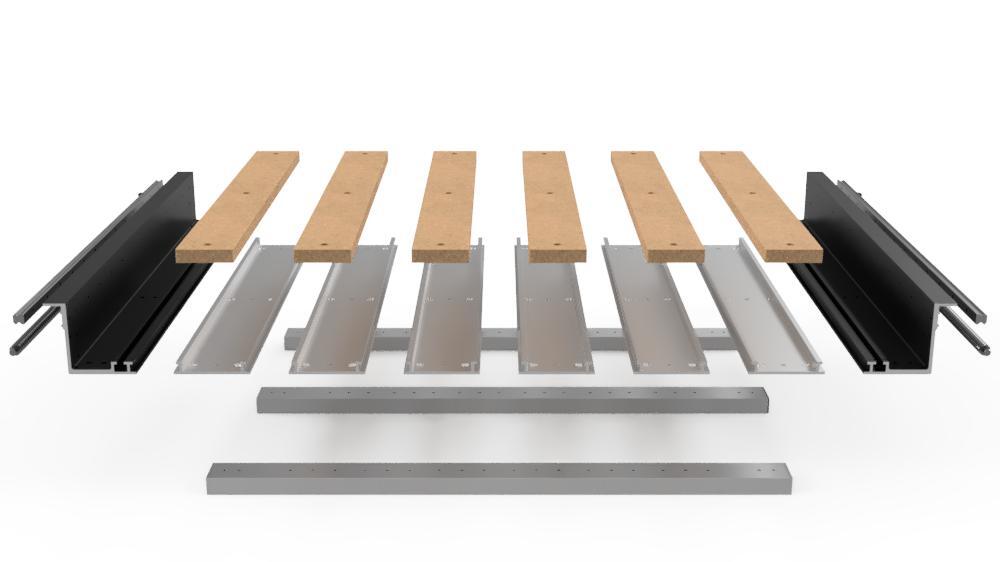

All of the Shapeoko machines are built on our Hybrid Table. It's a grid of custom extrusions that form a rigid base for the machine.

Believe it or not, other companies sell half a machine and expect you to bolt it to a sheet of wood. We think it's crazy to bolt a precision machine to a piece of wood that will flex and move with changes in temperature and humidity.

In addition to a rigid machine, the Hybrid Table also gives you a flexible workholding system to make it easy to hold all of your projects.

2. Simple Tool Changes

Unless you want to be limited to very simple projects, you're going to need to change tools. The problem is that tool changes can be error-prone and tedious if the machine does nothing to help out.

BitSetter makes tool changes easy. It's a combination of hardware and software that removes all of the complexity of tool changes, so you can focus on making parts.

3. Software

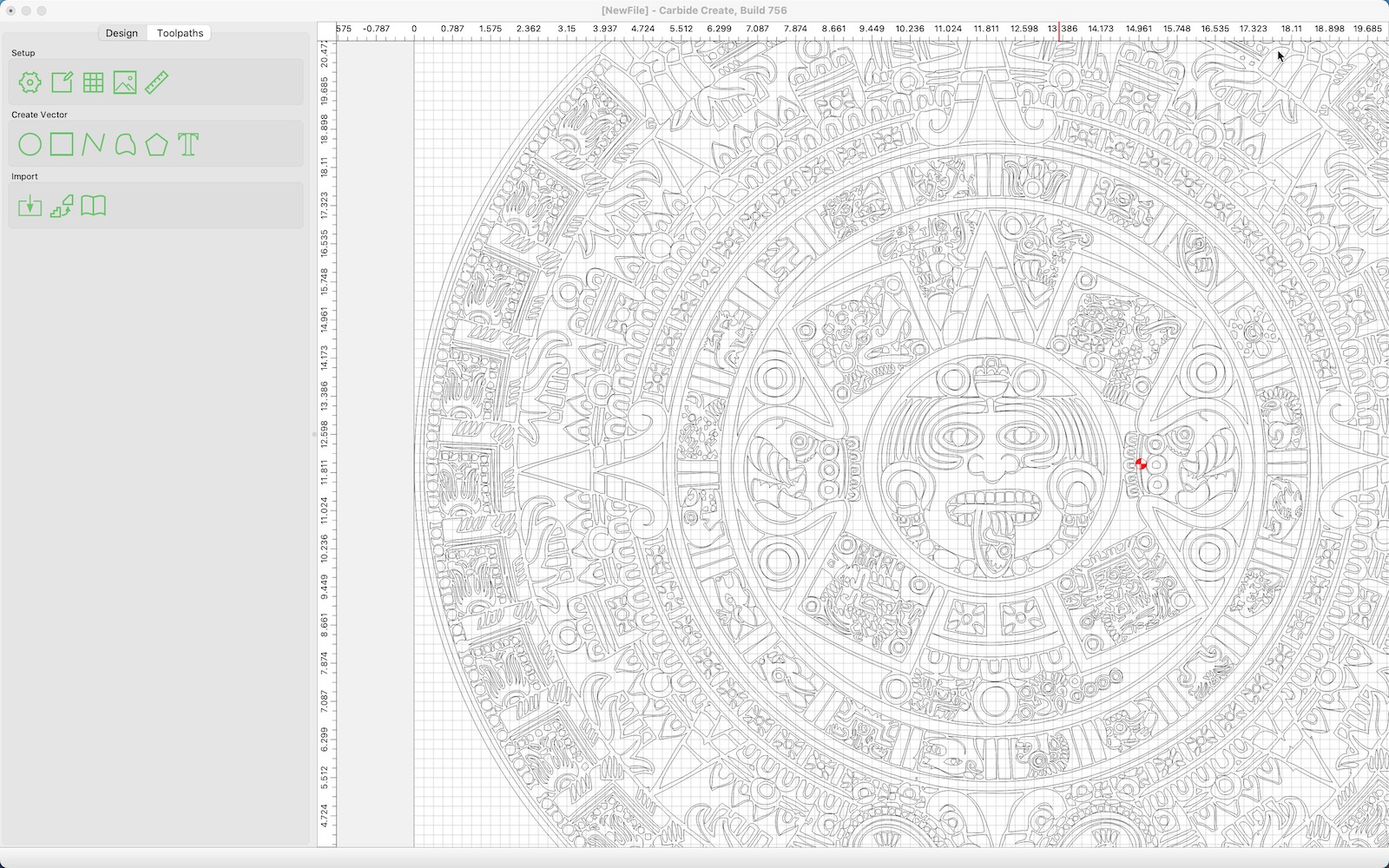

Carbide Create is our 2D design software, written from scratch so you can go from idea to part in minimal time.

It's easy to learn, and it's included with every Shapeoko at no additional cost, saving you hundreds of dollars.

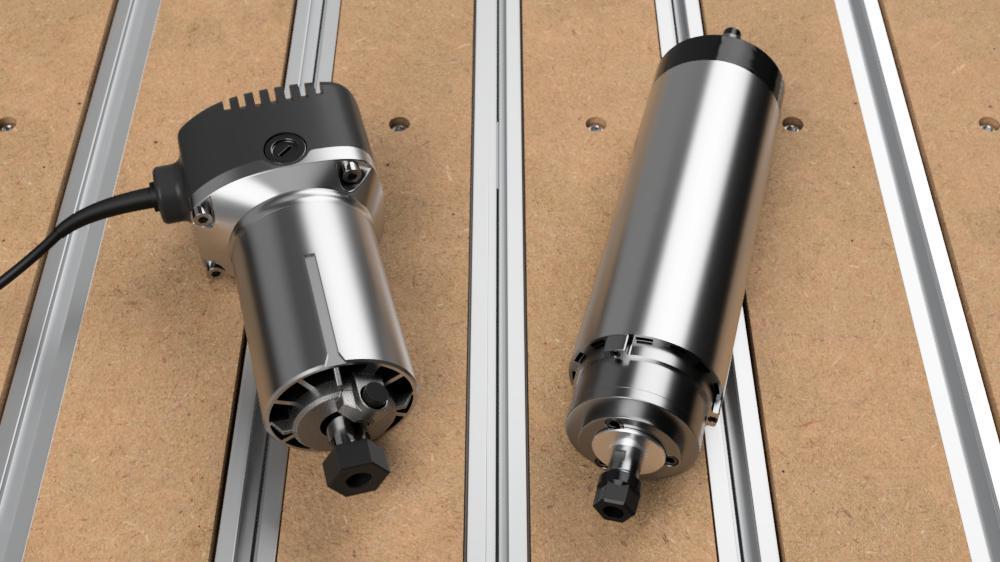

4. Choice of Spindles

Whether you're just going to use the machine casually, or you're going to run it all day, every day, we have a spindle that will fit your needs.

5. Value

Shapeoko includes everything you need to get started, so you won't be spending a lot of extra money before you can start cutting.

6. Value

For the first 60 days that you own your machine, we'll cover any damage to it, even if it's your fault.

You need to be able to learn without worrying about breaking anything.

7. Performance

All Shapeokos can cut a wide range of materials, from any kind of wood to plastic, aluminum, foam, wax, and more.

You can even use our MC Etcher Drag Bit to engrave glass, stone, and metal.

You'll be able to incorporate new materials into your projects with ease.

8. Productivity

Shapeoko is built to be robust and reliable enough to work as much as you want it to.

In fact, we've used both Shapeoko 4 and Shapeoko HDM machines in production for years making plastic parts for electronic enclosures.

We're not alone either, over half of Shapeoko owners make money with their machines.

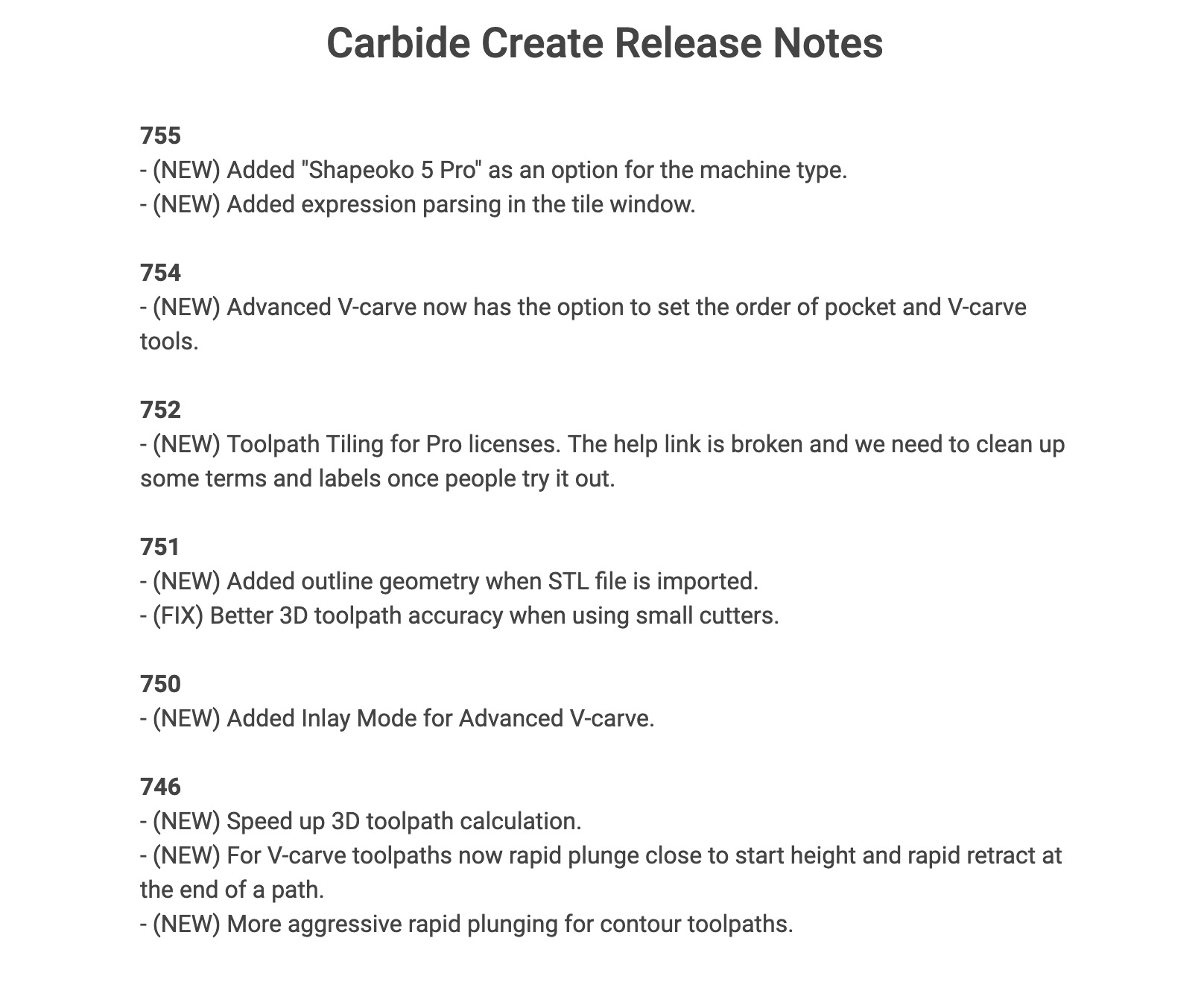

9. Updates

We've been updating our software since the company started, adding new features and capabilities.

Users who bought our very first machine almost 10 years ago are still getting free updates and finding their machines more capable than ever.

Your Shapeoko will likely end up with new features that never existed when you bought it.

10. Training

With over 5 hours of video training to help you learn your machine and software, you'll quickly move on to making projects.

If you've still got questions, you get four 30-minute 1-on-1 training sessions with a Carbide 3D expert to help you with your machine, software, or projects.

In addition to the training, you also have our free support, which is available to all Shapeoko owners.

Just in case you need a few more reasons to choose Shapeoko.

Shapeoko is designed and built in the USA. We're proud to support American manufacturing.

In addition to the 60-day mistakes policy, Shapeoko comes with a 12-month warranty against manufacturing defects.

Our support team is based in the USA and is available to help you with your machine, software, or projects.

Shapeoko has a large and active community of users that are always willing to help out.

CutRocket is our CNC project sharing site. It's full of free projects that you can download and make on your Shapeoko.

The Carbide3D Youtube Channel is regularly updated with projects, tips, tricks, and support information. It's an ever-expanding resource for Shapeoko owners.

Shapeoko has everything you're looking for in a CNC router. It's accurate, reliable, and affordable, so you can turn your workbench into a business.

We get asked this question a lot. There are a lot of CNC routers out there, and it can be difficult to know which one is right for you. Here are some things to consider when shopping for a CNC router.

Size: You'll want to make sure that the CNC router is small enough to fit comfortably in your shop space, but also large enough to handle the size of materials you'll be working with. If the machine lets you pass larger materials through the machine, you can cut parts larger than the machine's table size.

Ease of Use: Consider how user-friendly the machine is, especially if you're new to CNC routers. Look for a machine with an easy-to-use interface that allows you to quickly and easily set up your cuts. If the controls look too complicated in screenshots, they probably are in real life.

Rigidity: Look for a CNC machine that's built with sturdy components on a sold frame. Things like fully-supported rails and a rigid base go a long way to giving you repeatable, quality cuts.

Cost: A typical CNC router can range from a few hundred to hundreds of thousands of dollars. Don't look at the cost of the machine alone, but also the cost of the software, training, workholding, and other accessories you'll need to get started. Cheaper CNC machines can end up costing you a lot more to get up and running.

Customer Support: Look for a company that offers excellent customer support and technical assistance. A CNC machine is a significant purchase and you want to know that you're going to be able to get help if you need it.

Warranty: Things break. A good warranty will give you peace of mind and ensure that you're covered if something goes wrong.

Training: Look for a company that offers training and support beyond just getting the machine to move. Maybe you won't need the help, but it's nice to know that it's there if you need it.

Software: Be sure the machine comes with all the CNC software you need. If it doesn't be sure you know the additional cost, which can be significant.

Workholding: Nobody ever thinks about workholding before they buy a CNC router, but it's a critical part of the process. Be sure your CNC router comes with flexible workholding that will allow you to hold a wide variety of materials.

Dust Collection: Dust is the enemy of a CNC router, and it makes a mess of your shop. Be sure your CNC router comes with a dust shoe that will connect to your shop vacuum to keep your shop (and CNC machine) clean.

Shapeoko works with most free CNC software, but it also includes our Carbide Create so there's nothing more to buy.

Shapeoko takes 2-3 hours to assemble. Most of that time is spent on the Hybrid Table, which has a lot of screws, but the payoff is a rigid machine with great workholding.

Yes! Shapeoko can run 2D or 3D toolpaths with all motors moving simultaneously.

Shapeoko itself is very quiet. Most of the noise comes from the spindle (a trim router) and the shop vacuum, if you use one.

Unfortunately, we've done the math on the and it ends up being cost prohibitive to upgrade from a Shapeoko 4 to a Shapeoko Pro.

You cannot upgrade the size of a Shapeoko 4 or Pro. Upgrading from one size to another doesn't save much money from the price of a new machine.

Shapeoko 4 and Pro and use any 65mm spindle including the Carbide Compact Router, Makita RT0701C trim router, or our 65mm VFD spindles.

We have a lot of users running Vectric software with their Shapeoko.

Fusion 360 comes with a Carbide 3D post processor that works with Shapeoko.

Shapeoko can cut any type of wood from pine, to MDF, to hard woods like white oak.

Shapeoko can cut any common plastic including ABS, acrylic, polycarbonate, Delrin, HDPE, and PEEK

Shapeoko can cut aluminum but it will cut slower than wood and plastic so you'll want to take your time with it.

Shapeoko can cut brass but it will cut slower than wood, plastic and aluminum so you'll need to take your time with it.

Shapeoko can cut brass and aluminum but harder metals, like steel or stainless steel, are not recommended. Many users have done it, but cutting steel takes a lot more skill and experience.

We'll keep you up to date on new things in the world of Carbide 3D, and CNC in general.