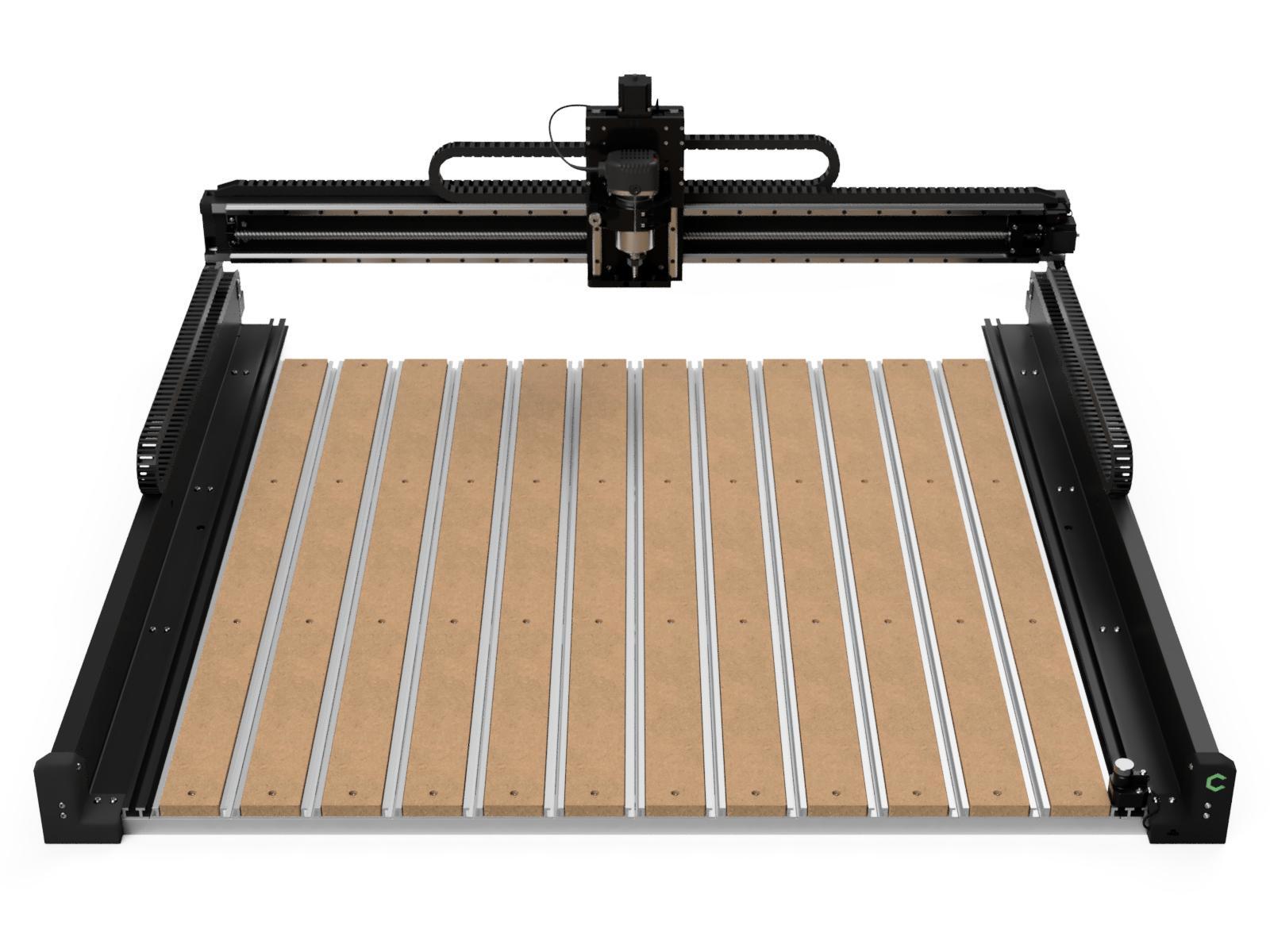

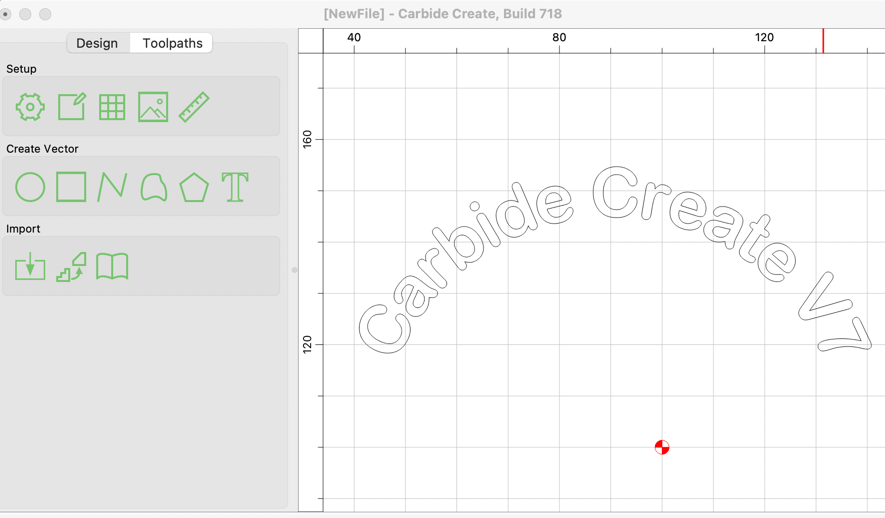

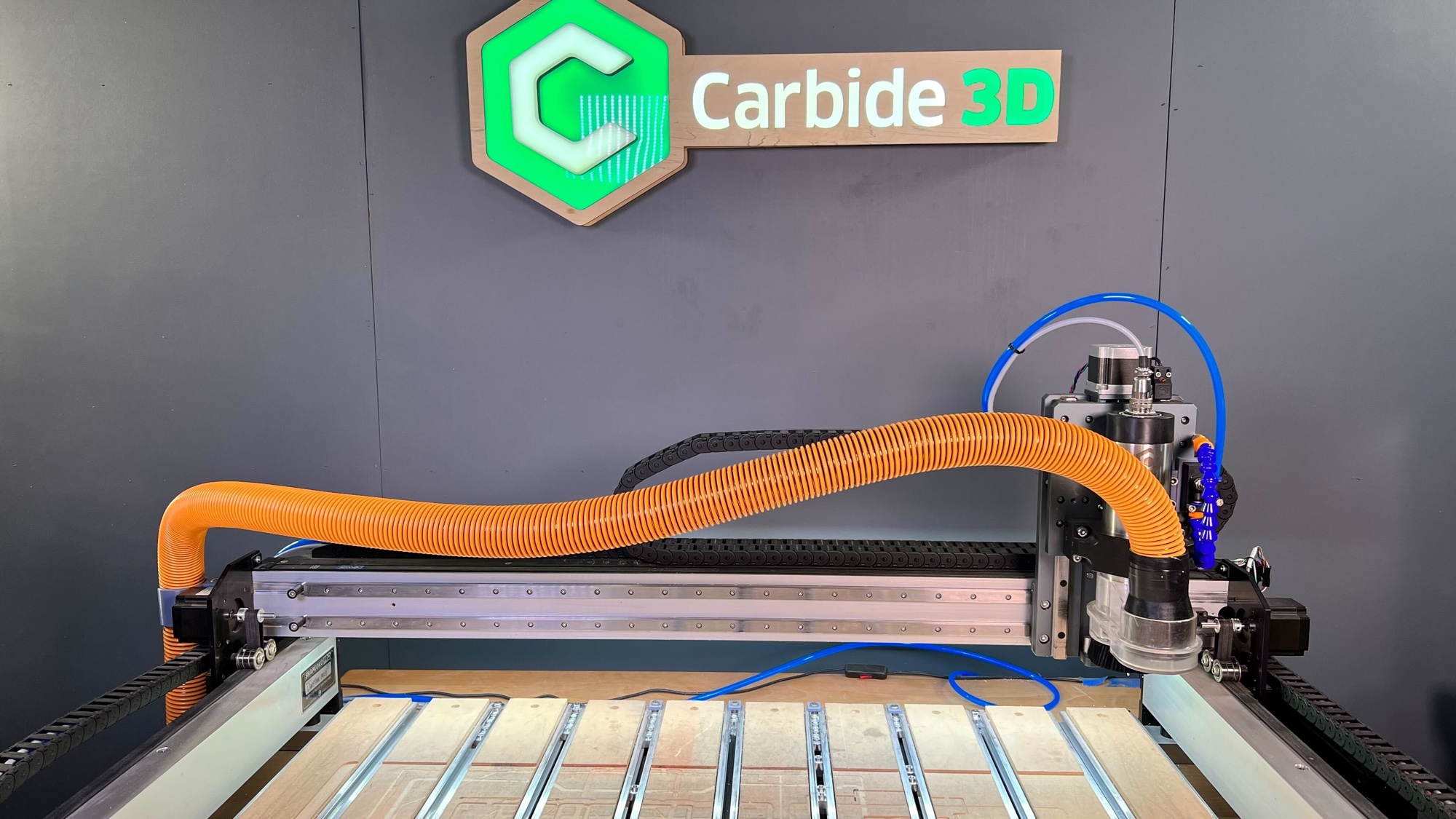

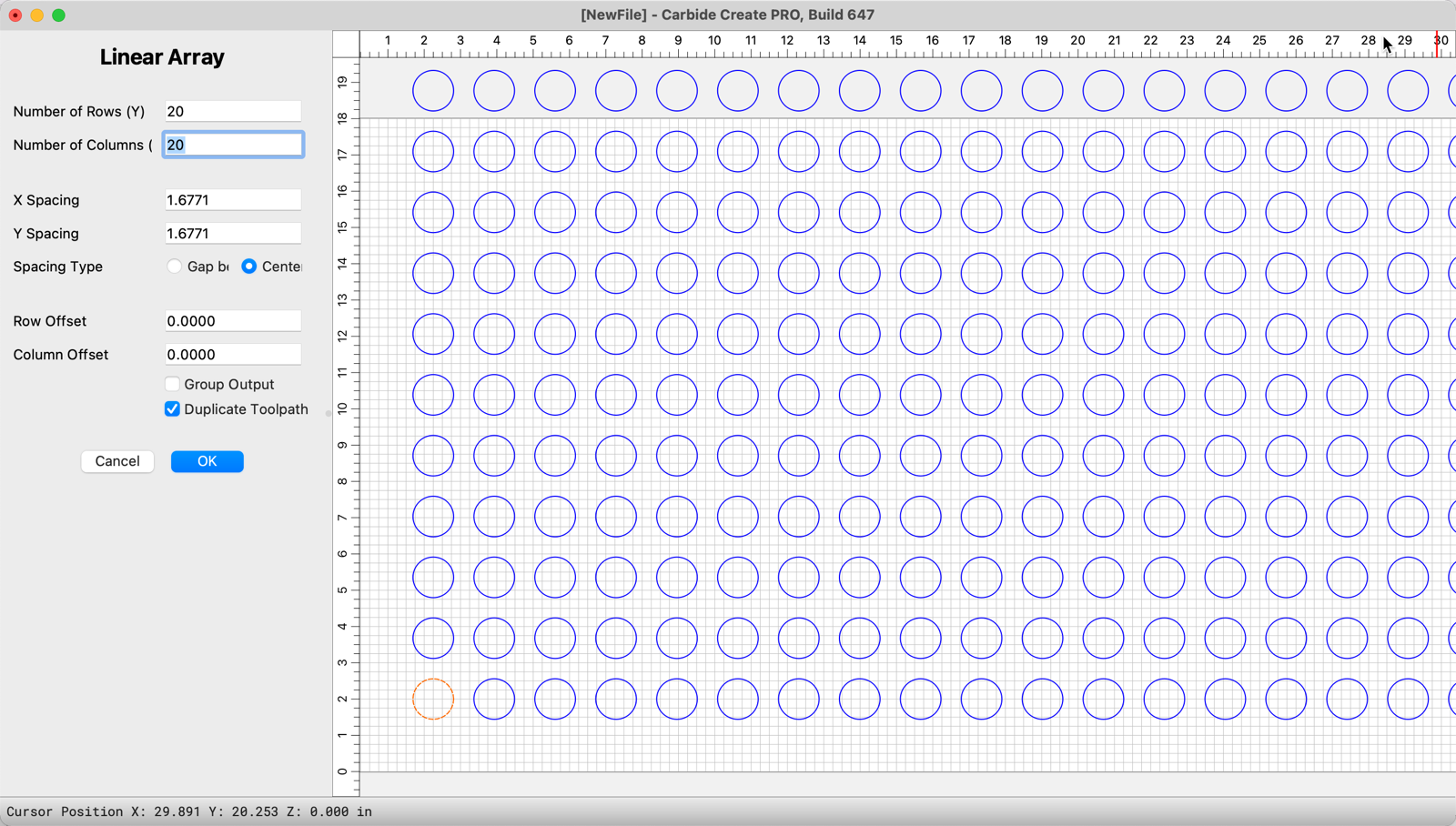

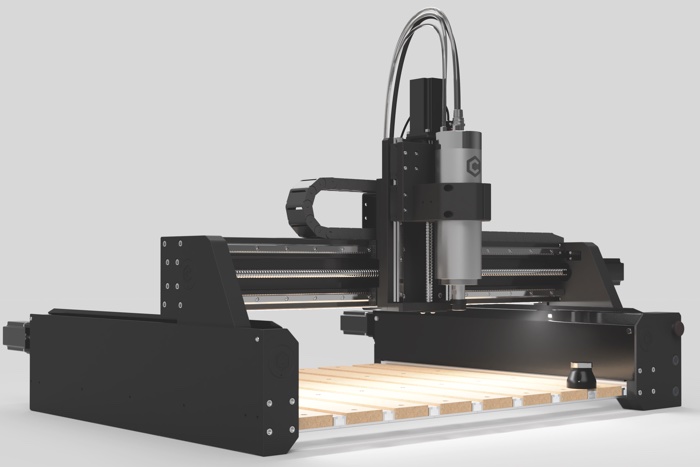

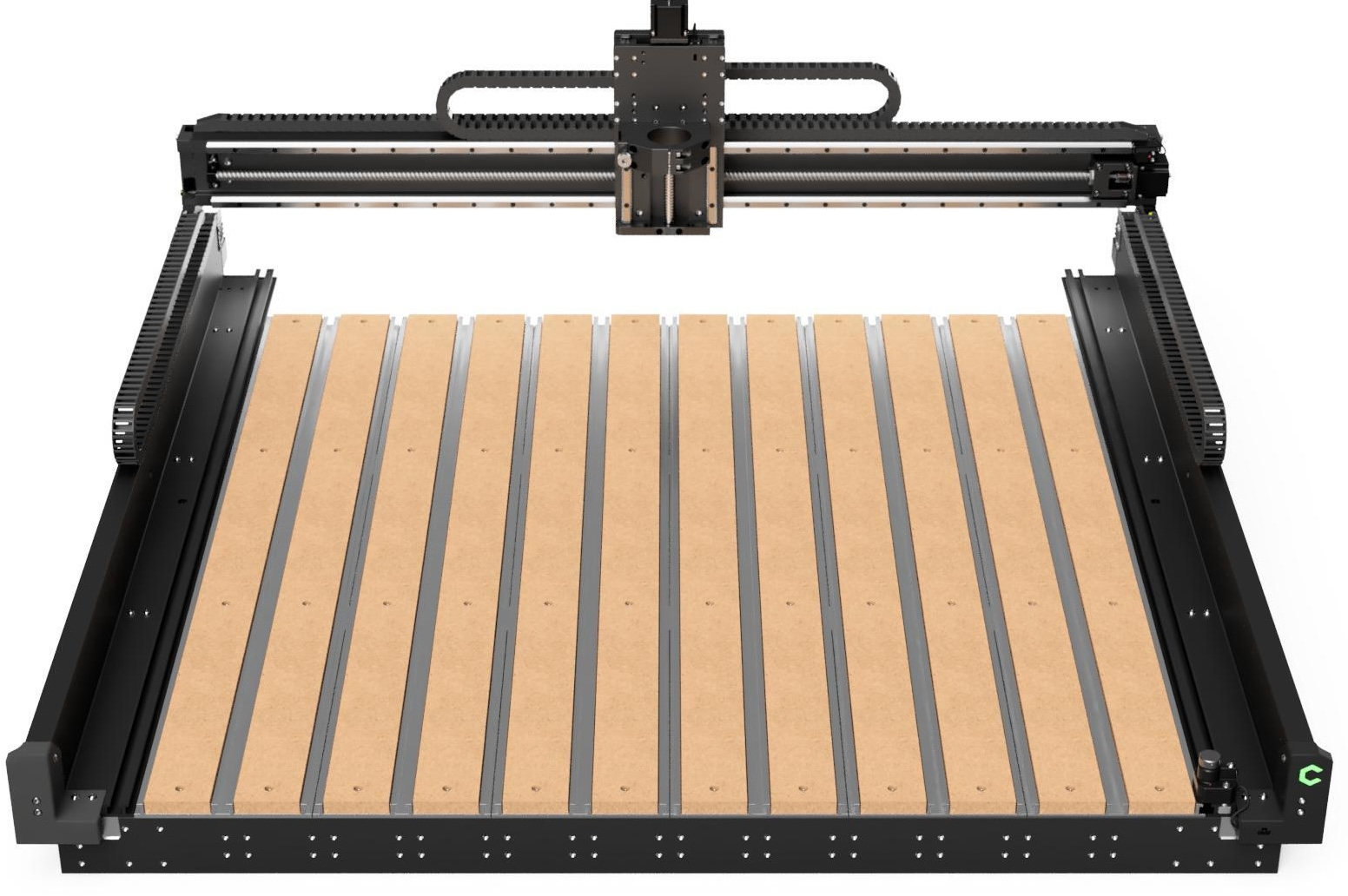

The Shapeoko 5.1 Pro is Here!

We quietly make changes to the Shapeoko 5 Pro all the time, but most of them are not things that the average user would ever notice. Today, we're ready to share the latest change, which has already been shipping- the Shapeoko 5.1 Pro.